Course Information

DMAIC Basics Training

Learners will be able to:

- Participate on a project team using the DMAIC methodology.

- Use tools and techniques to get to the root cause of a problem.

- Develop action plans to prevent the same problems from recurring.

About This Course

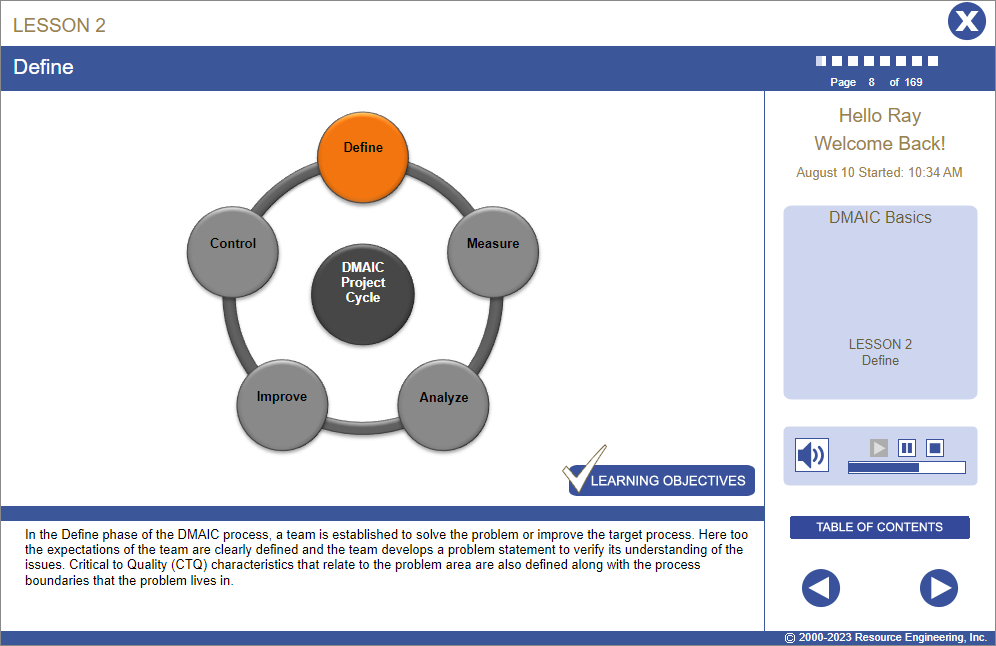

DMAIC Problem-Solving (Define-Measure-Analyze-Improve-Control) is a step-by-step problem-solving methodology used by many Lean Six Sigma companies. With the DMAIC problem-solving process, teams address and solve problems by uncovering and eliminating the root cause of the problem through a structured series of steps using data collection and data analysis tools and techniques.

DMAIC Basics online training consists of six lessons and a Challenge intended to allow learners to test their comprehension of the body of knowledge covered in the course. The course content begins with a short lesson introducing the five phases of the DMAIC project cycle. The five lessons that follow work through the Define, Measure, Analyze, Improve and Control phases sequentially.

- Learners should have a specific team problem-solving project in mind to work on before taking this course.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe each of the steps of the DMAIC process.

- Learn how to use a structured process to solve problems.

- Work on a problem-solving team.

- Use data collection and analysis tools to find and solve problems.

- Ensure that solutions are robust, effective and continue to work.

Course Outline

Lesson 1 | Introduction

- What is DMAIC and how does it compare to other problem-solving models?

Lesson 2 | Define

- Establish a project (problem-solving) team and get the team started up.

- Develop the Problem Statement.

Lesson 3 | Measure

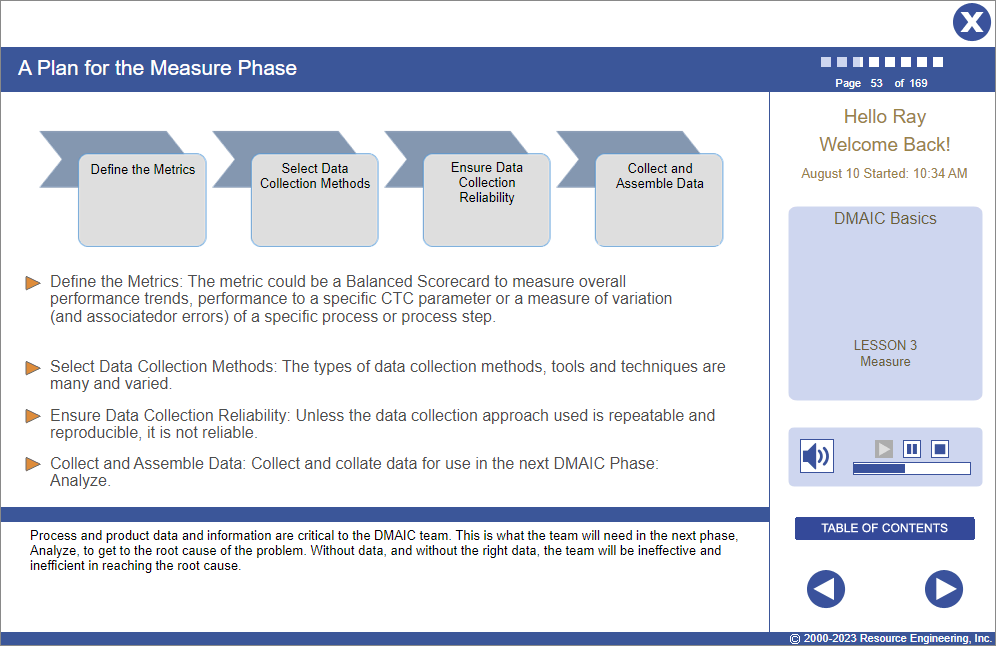

- Set up measurement systems so that the appropriate data needed to determine the root cause of the problem can be collected.

- Assess measurement systems to make sure they are reliable.

Lesson 4 | Analyze

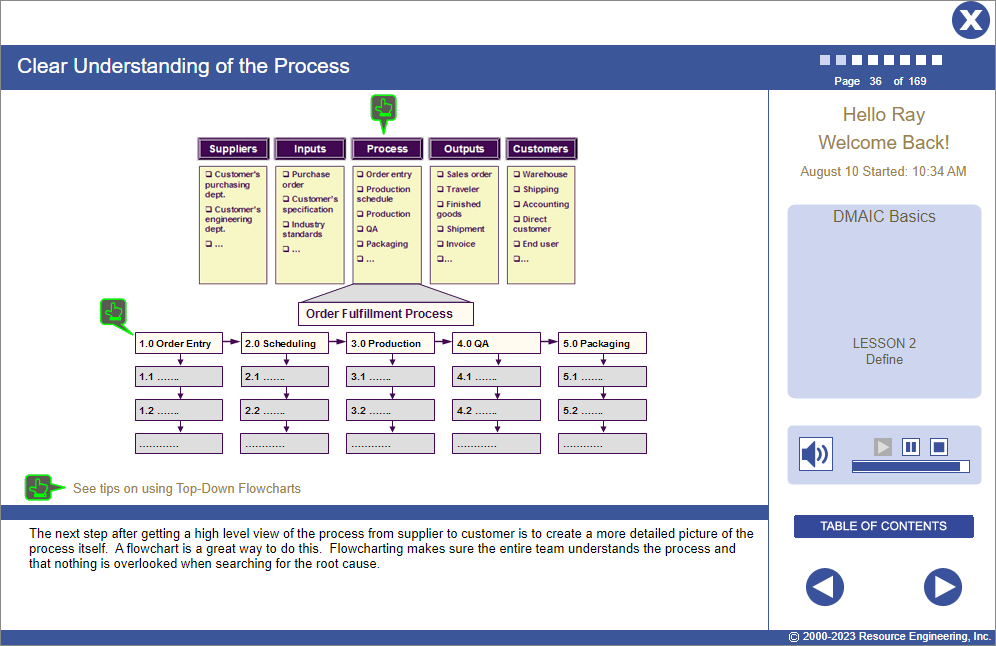

- Use a systematic approach to collect, display, and analyze data to identify the root cause(s).

- Verify that the cause(s) identified is truly the root cause.

- Identify a solution to attack the root cause and correct the problem.

Lesson 5 | Improve

- Execute the problem solution.

- Develop simple and complex action plans.

- Use Gantt Charts to plan the implementation and monitor progress.

Lesson 6 | Control

- Ensure the solution is robust and well entrenched so that problem does not come back.

- Provide training and start audit practices to complete transfer of the solution to the process owners.

Challenge

- An assessment of the learner’s progress in this course.

4.7 out of 5 stars

Comments from Learners About This Course

- I personally enjoyed this course.

- DMAIC Basics is an excellent introduction to this quality oriented philosophy.

- Great content

You may also be interested in…

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.

- Five Why’s – Focused training in how to use the Five Why’s technique to get to the root cause of problems.

- Root Cause Analysis with Corrective Action – Leads the learner through a four-step process to get to the root cause (source) of problems to eliminated problems for good.