Course Information

Lean Implementation Training

Learners will be able to:

- Develop an effective start-up approach for a Lean initiative.

- Create a plan for a controlled Lean pilot as the first step in implementing Lean.

- Avoid common pitfalls that cause Lean initiatives to fail.

About This Course

What is Lean Manufacturing?

Simply put, lean organizations are customer-focused. They reduce waste in their value streams by improving workflows and then by subsequently improving the physical layout of their facilities. Process capacity is managed and actually increased by reducing set-up times, improving quality, and ensuring equipment works when it is counted upon to work.

Successful implementation of a lean initiative will improve an organization’s marketplace and financial performance. However, many aspects of lean are counter-intuitive to traditional manufacturing thinking and practices. It is vital that organizations adopting a lean approach understand the scope, the many elements, and the potential pitfalls of lean.

Implementing Lean Online Training

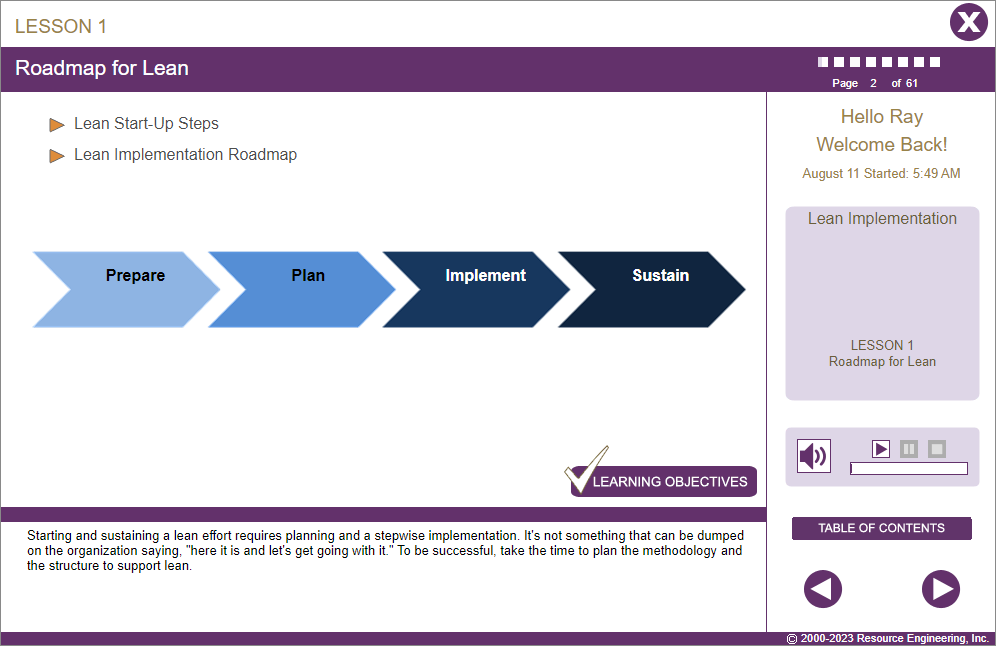

This course introduces leaders and managers to a step-by-step implementation plan and roadmap for implementing Lean.

- Understanding of terminology and philosophy of Lean Manufacturing such as Overview of Lean or equivalent.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Understand the reasons for implementing Lean in an organization.

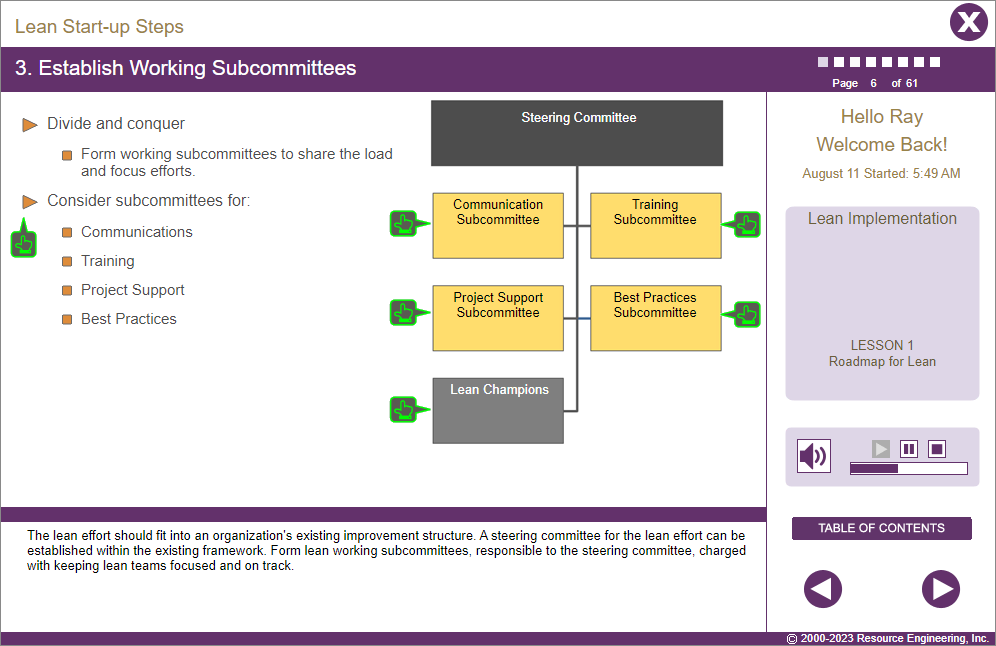

- Briefly describe the lean start-up steps.

- Explain the importance of a pilot in getting a lean effort off to a solid start.

- Describe what “cross-functional and interdependent departments” means.

- Define customer-focused and flexible, adaptable, and resourceful and explain what they mean to a lean environment.

- Identify the 12 most common reasons a lean initiative fails.

Course Outline

Lesson 1 | Roadmap for Lean

- Start with the people issues.

- Focus on workplace organization (the 5S’s), then, use value stream analysis and process workflow analysis to establish effective layouts.

- Where to focus next depends on specific needs.

- Use targeted Kaizen events to speed changes.

- Do not overlook the need to modify support processes (especially scheduling and purchasing).

Lesson 2 | Lean Leadership

- Lead by example.

- Communicate the why, what, how, and who.

- Provide education in the concepts.

- Train employees in tools and techniques as needed to achieve a flexible workforce.

- The Lean Roadmap is not linear.

Lesson 3 | Pitfalls with Lean

- Not documenting the financial impact/savings.

- Lack of commitment from leadership.

- Using traditional purchasing practices.

- Not changing scheduling techniques.

- Failure to address workforce issues.

- Not mistake-proofing the root cause.

- Thinking Lean is just for manufacturing.

- Not using beneficial technology.

- Not leveraging successes.

- Getting too lean.

- Failure to hold the gains.

Challenge

- An assessment of the learner’s progress in this course.

4.9 out of 5 stars

You may also be interested in…

- Lean Manufacturing – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a manufacturing environment.

- Lean for Business Processes – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a transaction-based/non-manufacturing business or job function.