Course Information

5s Training: Workplace Organization

Learners will be able to:

- Remove clutter to free up workspace.

- Organize work aids and supplies for time-saving efficiency.

- Implement strategies to maintain and build on the improvements and share with others in the organization.

About This Course

With this 5S training, participants will be able to apply each of the 5S’s on their own or as part of a team. They will transform their workspace from a cluttered, cramped area to a clean and highly functional space.

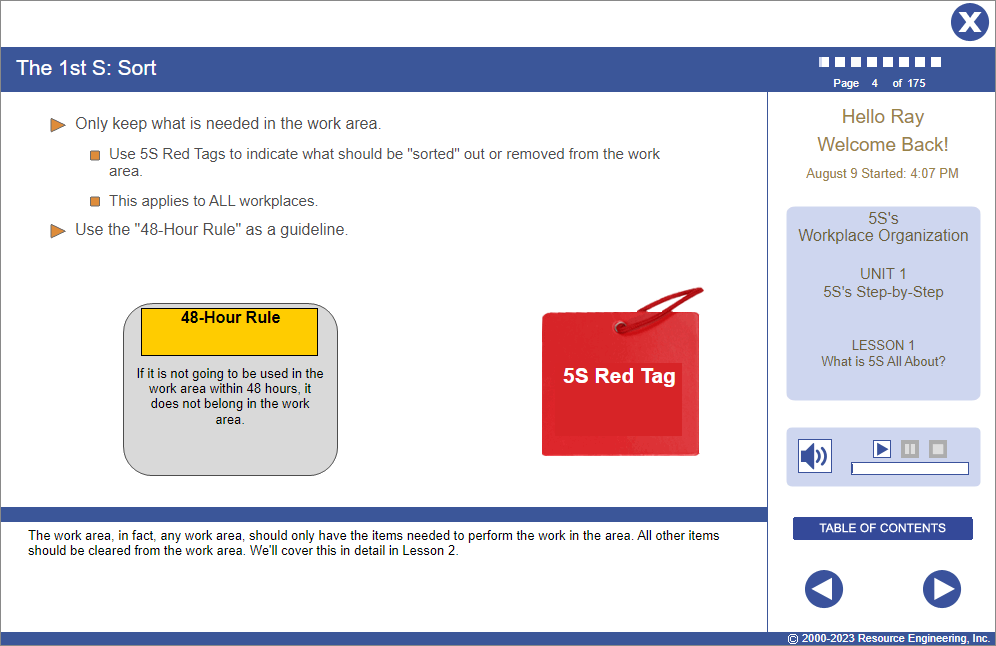

Beginning with Sort, learners will be able to use the 48-hour rule to remove clutter and distracting items from the immediate work area and then create designated locations for everything based on how often it is used in the Set in Order step. The Shine step inspires learners to do an initial deep cleaning of the workspace, and then helps them develop a strategy for keeping the area clean in the future. The last two steps, Standardize and Sustain expand the 5S’s throughout your organization and assure that they become standard operating procedure for everyone in your company.

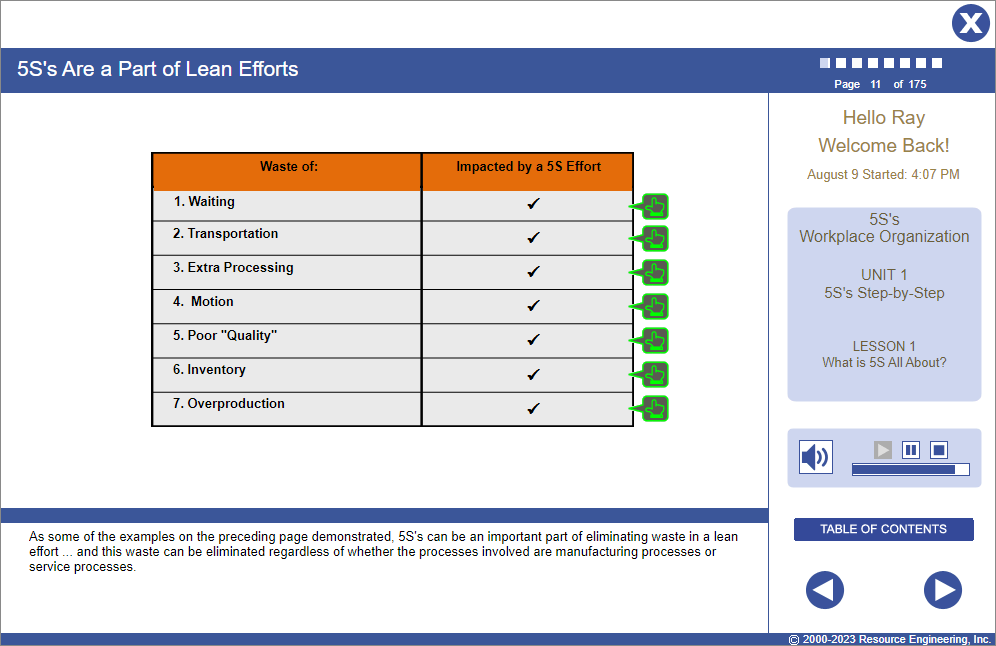

Instituting the 5S’s is usually one of the first step companies take in implementing Lean Six Sigma. The 5S’s (Sort, Set in Order, Shine, Standardize, and Sustain) are rough translations from the original Japanese terms referring to a process to optimize workplace organization. The premise for the 5S’s is that a lot of improvements and inefficiencies can be made by having a clean, organized and efficient workplace.

With this online training course, employees will learn the fundamental concepts of the 5S’s that will improve quality and productivity. This course includes step-by-step guidelines for achieving the 5S’s as well as a roadmap to implement the 5S’s throughout the entire organization. Many examples of 5S success stories are included throughout the training.

- Learners should have the ability/authority to make improvements in their work area.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

Unit 1 | The 5S’s Step-by-Step

In this unit learners will be introduced to the five core components of the 5S’s:

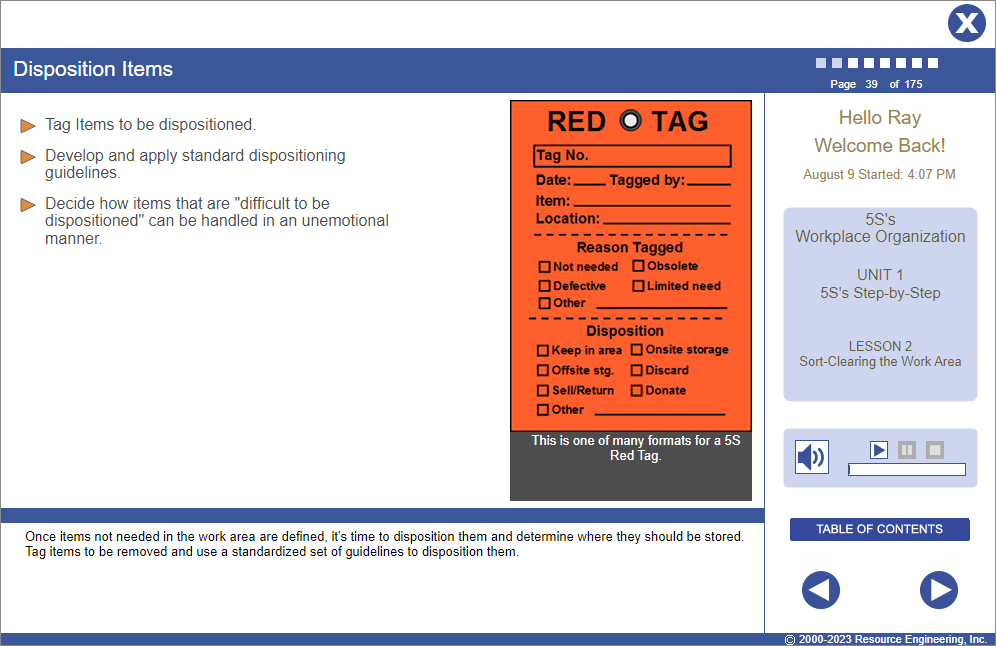

- Sort: Sort out items not needed in the work area and disposition those items to be removed.

- Set in Order: Select the best locations and ways to store items used in the work area using a structured rationale and knowledge of storage options.

- Shine: Get the workplace clean; then maintain the appearance of the workplace and institute preventive measures to ensure it stays clean.

- Standardize: Design systems in place to ensure everyone does things the same way, implement techniques to ingrain a “copy exactly” mind set, and leverage Best Practices.

- Sustain: Learn how to prevent backsliding and build the 5S’s into the culture of the organization.

Unit 2 | 5S Implementation

In this unit, learners explore approaches to implement the 5S’s in their organization (or work area); examples of successes for each 5S phase are included.

- Organization-Wide Implementation: Work though an 8-point checklist to plan an organization-wide implementation of the 5S’s.

- Work Area Implementation: Use a 6-point checklist to plan your work area 5S effort if a site-wide 5S implementation is not supported.

- Sort Successes: Explore examples of “Sort Successes” to trigger ideas for your 5S effort.

- Set in Order Successes: Use lessons learned from “Set in Order Successes” to fuel your 5S effort.

- Shine, Standardize, & Sustain Successes: Adopt the examples discussed to build success factors into your Shine, Standardize, and Sustain efforts.

Course Outline

Unit 1 The 5S’s Step-by-Step

Lesson 1 | What is 5S All About?

- An overview of the 5S’s.

- The benefits and operational impact of implementing the 5S’s.

Lesson 2 | Sort: Clearing the Work Area

- How to organize the work area for efficiency and effectiveness and use the “48-Hour Rule.”

- A stepwise approach to clear the work area.

Lesson 3 | Set in Order: Designated Locations

- How to designate “a place for everything” and ensure “everything is in its place.”

- Considerations for establishing locations for storing items including: storage rationale, storage options, location-specific tips, storage don’ts, using signs and labels and documenting the plan.

Lesson 4 | Shine: Cleanliness and Workplace Appearance

- The three aspects of Shine: getting the workplace clean, maintaining its appearance, and using preventive measures to keep it clean.

Lesson 5 | Standardize: Everyone Doing Things the Same Way

- How to design systems that helps ensure that everyone does things the same way with full involvement, standardized training, and a “copy exactly” mindset.

Lesson 6 | Sustain: Ingrain It in the Culture

- How to implement techniques to prevent backsliding to sustain and ingrain workplace organization

Unit 1 Challenge

- An assessment of the learner’s progress in this unit.

Unit 2 5S Implementation

Lesson 1 | An Organization-Wide 5S Effort

- How to plan and implement a 5S initiative.

- An 8-point roadmap to implement the 5S’s: 1: Leadership Team; 2: Infrastructure; 3: Communications; 4: Training; 5: 5S Pilots; 6: Best Practices; 7: Full Roll-Out Plan; 8: Evaluate and Adjust.

Lesson 2 | Tackling 5S’s on Your Own

- How to implement the 5S’s in a work area if an organization-wide initiative is not supported.

Lesson 3 | Success Stories: Sorts

- Examples of “Sort Successes” showing both the before-state and the after-state with the impact (savings) explained.

- Checklist to help achieve successful Sorts.

Lesson 4 | Success Stories: Set in Order

- Examples of “Set in Order Successes” showing both the before-state and the after-state complete with the impact on the organization.

- Set in Order Checklists.

Lesson 5 | Success Stories: Shine, Standardize and Sustain

- Examples of successful approaches for the Shine, Standardize and Sustain phases of a 5S program

Unit 2 Challenge

- An assessment of the learner’s progress in this unit.

4.7 out of 5 stars

Comments from Learners About This Course

- Total 360 approach to 5S presents all aspects a team needs to overcome the challenges of implementing 5S.

- The course is very interesting as it helps us work and organize processes more efficiently.

- This is a quality course that explained the 5S system well.

- Awesome 5s course with detailed explanations.

- This course opens your eyes to the meanings of each S. This is very good training.

- Course was extremely informative and thorough.

- Great course defining the 5s importance in almost all parts of a company’s framework.

- It is an excellent course. It has all the basics, and it goes deep gradually. It covers everything that you need to know to go on this very challenging journey of Lean. A great course. I will recommend it to interested people. Thank you so much.

- Training at 5S was very interesting, mind opening and educating. Approachable form and full of useful information. Recommended to everyone.

You may also be interested in…

- Lean Manufacturing – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a manufacturing environment.

- Lean for Business Processes – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a transaction-based/non-manufacturing business or job function.

- 8D Problem-Solving – Step-by-step training in how to work on a problem-solving team follow the 8D methodology including tools and techniques that are used in each step.