Course Information

AIAG-VDA Design FMEA Training

Learners will be able to:

- Participate as a core member of an AIAG-VDA Design-FMEA Team.

- Rate the risk of potential failure modes using Action Priority Levels.

- Develop action plans to address risks that are unacceptably high.

About This Course

Failure Mode and Effects Analysis (FMEA) techniques have been used for over 70 (yes, SEVENTY!) years. In recent years, use of FMEAs has gained popularity as a quality improvement tool. Most industries are now using FMEA techniques as part of their risk assessment and risk mitigation strategies. Unlike many quality improvement tools, FMEAs do not require complicated statistics. FMEA studies can yield significant savings for a company as well as reduce potential risks and associated liabilities of a product or process that does not perform as intended.

In 2019, AIAG (Automotive Industry Action Group, www.aiag.org) and VDA (Verband der Automobilindustrie, www.vda.de), two of the leading automotive trade associations, unveiled a major revision to FMEA methodology with the release of the AIAG-VDA FMEA Handbook.

This online training prepares learners to participate on the core team of a Design-FMEA (DFMEA) using the 2019 AIAG-VDA FMEA Process. The course provides a background understanding of FMEAs, provides detailed instruction for participating on a DFMEA Core Team and conceptually introduces FMEAs for Monitoring and System Response (FMEA-MSR).

IMPORTANT NOTE: While the AIAG-VDA Design FMEA course is in line with the AIAG-VDA FMEA Handbook, it is not intended as a replacement for the source Handbook. We recommend that this course be used in conjunction with the official Handbook.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe the systematic approach that FMEAs take to identify and reduce risks.

- Compare and contrast the different types of FMEAs and describe the relationship between DFMEAs and FMEA-MSRs.

- Define what the Five T’s are and explain how they are used to ensure successful FMEA team start-ups.

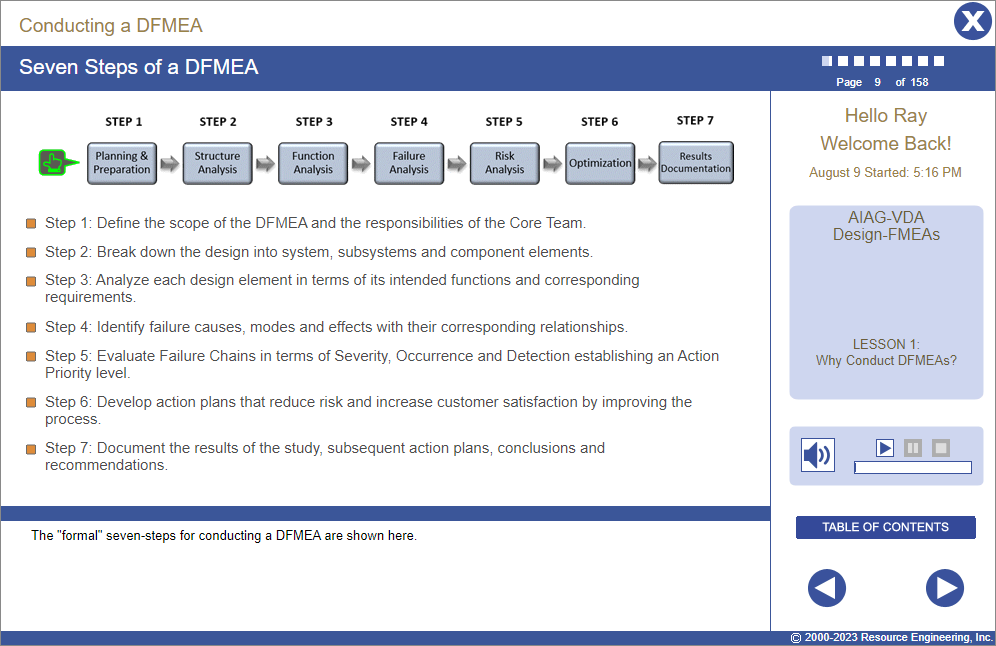

- Learn to use the Seven-Step AIAG-VDA DFMEA process.

- Describe the “Failure Chain” concept in FMEAs.

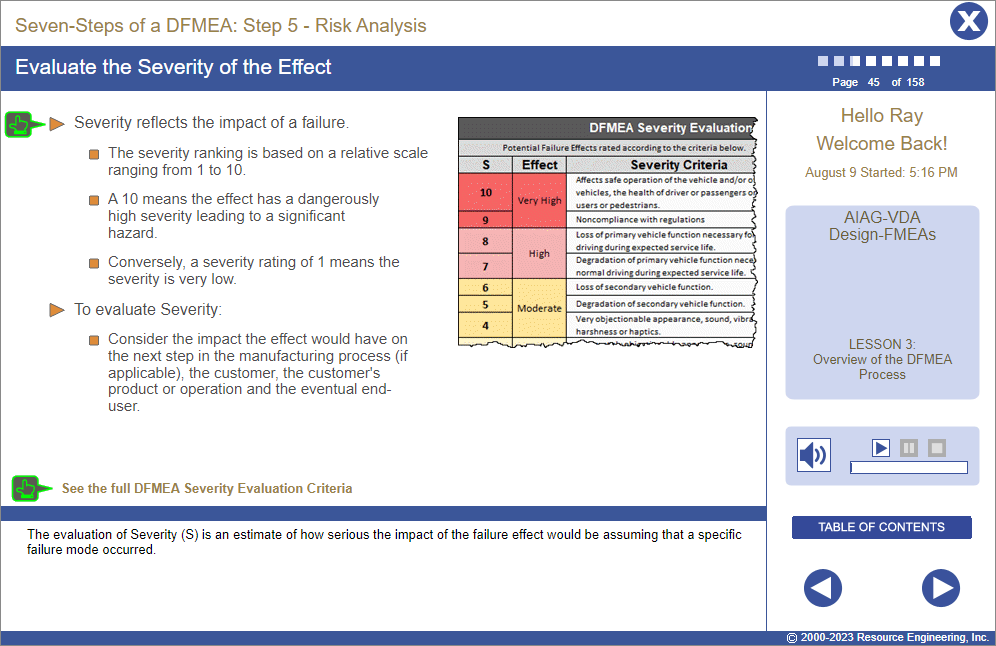

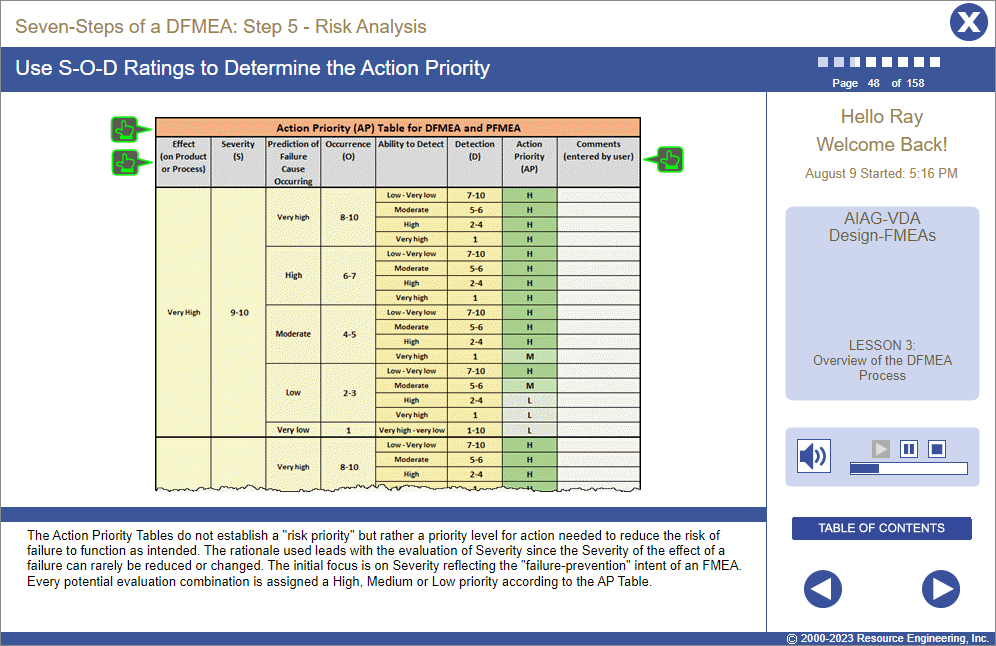

- Understand how evaluation criteria is used to rate the levels of Severity, Occurrence and Detection and how the S-O-D rating is used to establish the Action Priority Level of potential failure modes.

- Develop action plans to reduce risks and make the process more robust.

- Understand what FMEA-MSRs are and how they supplement DFMEAs.

- Identify key factors to improve the effectiveness of DFMEAs.

Course Outline

Lesson 1 | Why Conduct DFMEAs?

- Know what a DFMEA is and why a DFMEA is used.

- Understand how a DFMEA is conducted on a conceptual basis.

Lesson 2 | Brief History of FMEAs

- To gain an appreciation of the historical evolution of FMEAs, the types of FMEAs that are used and the industries that use them.

Lesson 3 | Overview of the DFMEA Process

- To understand the scope and scale of the seven-step DFMEA process.

Lesson 4 | System Analysis (Steps 1, 2 & 3)

- To appreciate how to charter and start-up a DFMEA team.

- To understand how to analyze the structure of the design under study.

- To learn how to identify the functions of each design component.

Lesson 5 | Failure Analysis and Risk Mitigation (Steps 4, 5 & 6)

- To understand the concept of a Failure Chain.

- To use the Failure Chain model to identify failure modes, failure effects and failure causes for each design element.

- To realize how to use Evaluation Criteria to rate the Severity, Occurrence and Detection for each failure.

- To understand how to create custom Evaluation Criteria.

- To learn how to use the Action Priority Tables to assign AP Levels.

- To use common problem-solving tools to develop risk mitigation plans.

Lesson 6 | Communication (Step 7)

- To know how to document and communicate DFMEA results.

Lesson 7 | Overview of FMEA-MSRs

- Understand what FMEA-MSRs are and how they supplement DFMEAs.

Lesson 8 | Helpful Tips

- To be aware of approaches that can help teams conduct DFMEAs more effectively and efficiently.

Challenge

- An assessment of the learner’s progress in this course.

4.8 out of 5 stars

Comments from Learners About This Course

- Best course, which gives the overview of the DFMEA

- This course was very well written with great examples to work with.

- The training materials are fantastic. FMEA is a very good tool. Everyone should master it.

- This course clearly introduces the relevant knowledge of DFMEA, which will be of great help to the future application.

- Excellently made content, self explanatory and right to the point.

- Very interesting and informative course. Useful tips and examples are given throughout the course with supplemental information, such as checklists as pop up windows.

- Very thorough and really helped me get a handle on some of the new ways of thinking about how to perform a DFMEA using the AIAG-VDA approach.

- Brand new information to me – very informative and helpful – able to create applicable relationships with my position and training.

- Excellent course, have taken part in many DFMEAs but this course provided much needed context to some of the terms.

- An excellent course to learn every characteristic and function of FMEA.

- Very good training! and good support information to understand the New requirements of the customers.

You may also be interested in…

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.

- 8D Problem-Solving – Step-by-step training in how to work on a problem-solving team follow the 8D methodology including tools and techniques that are used in each step.

- Root Cause Analysis with Corrective Action – Leads the learner through a four-step process to get to the root cause (source) of problems to eliminated problems for good.