Course Information

DOE: Screening Experiments Training

Learners will be able to:

- Describe the family of DOEs and explain the objective of each.

- Conduct a Plackett-Burman screening experiment.

- Conduct a Taguchi screening experiment.

About This Course

Screening Experiments are the most powerful of Design of Experiments techniques for uncovering the power factors in a manufacturing process. With a small number of experimental runs and very little data, you can make significant improvements to processes. The most common screening experiment techniques – Taguchi and Plackett-Burman techniques are covered in detail in this course.

Now you can learn how to conduct DOE screening experiments with this comprehensive online training program in the comfort of your own office. By learning the powerful Design of Experiments techniques developed by Plackett-Burman and Taguchi you will be able to set-up and conduct your own in-house DOE screening experiments without outside consultants or seminars.

Because this training is self-paced, you can develop your own experimental design as you go through the training. DOE worksheets and step-by-step DOE instructions will guide you through the process. If your company is implementing a lean six sigma initiative, you know how important it is to optimize your manufacturing processes with DOE. This Design of Experiments training course will give you the tools you need to get the most from this powerful statistical quality improvement technique.

- Basic math skills.

- A basic understanding of statistics and concepts of variation.

- Basic SPC and Advanced SPC or the equivalent.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

Unit 1 | Background for DOE

- Why design of experiments (DOE) are more efficient and effective than one-at-a-time (OAT) experimentation.

- What the major terms used in designed experiments mean.

- Types of designed experiments and when they are best used.

- How to use basic tests of significance.

- How to plan a designed experiment.

Unit 2 | Plackett-Burman Techniques

- How Plackett-Burman designs were derived.

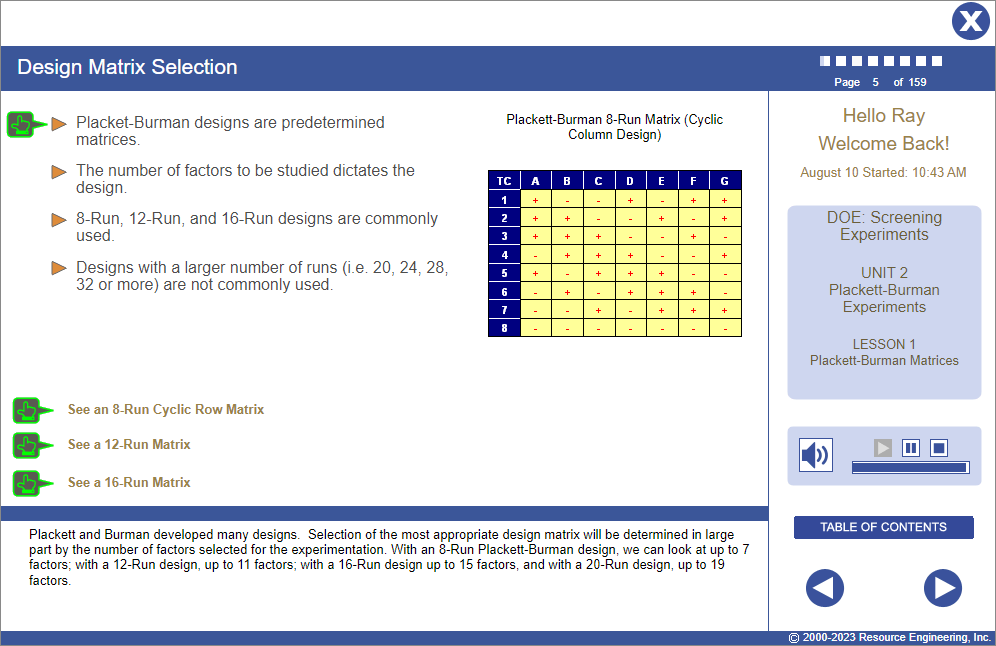

- How to determine which Plackett-Burman matrix to use for your application.

- How to estimate the experimental error in Plackett-Burman experiments.

- How to analyze experimental results and calculate the statistical significance of factor effects.

- How to develop a prediction equation that can be used to optimize the response.

- How to salvage experiments if data are lost.

Unit 3 | Taguchi Techniques

- Why Taguchi techniques focus on the robustness of the product.

- How the Quality (Taguchi) Loss Function is used.

- How to calculate and use Signal to Noise ratios.

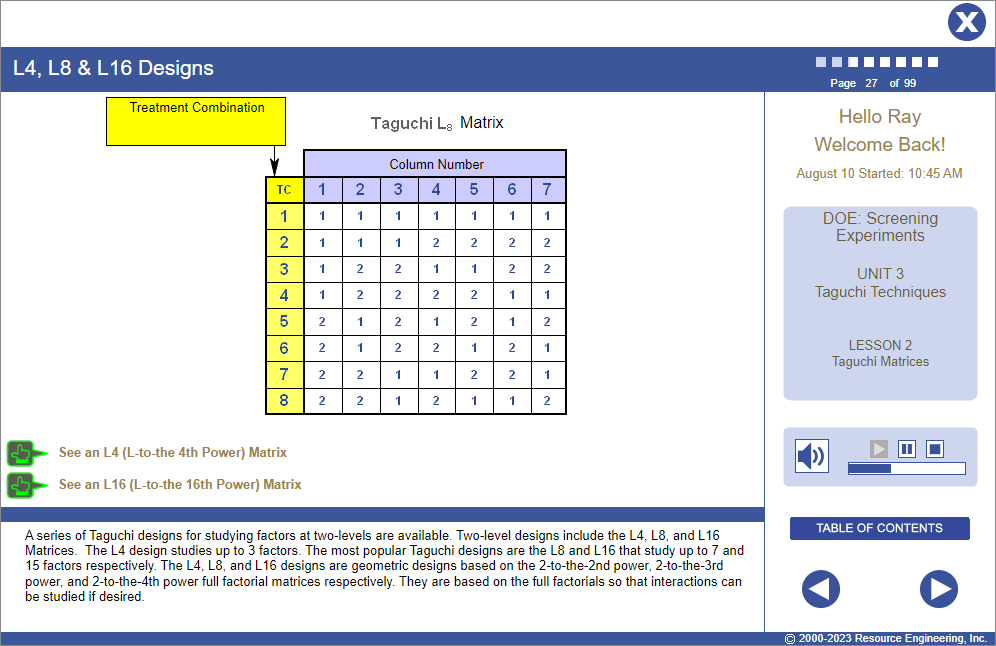

- How Taguchi designs were derived.

- How to determine which Taguchi design to use for your application.

- How to use Taguchi interaction tables.

- How to test the statistical significance of factor effects.

- How to develop a prediction equation that can be used to optimize the response.

- How to use mean, S/N, and variation effects to determine where to set factors.

- How to salvage experiments if data are lost.

Course Outline

Unit 1 Background for DOE

Lesson 1 | Why DOE?

- Limitations of OATs (one-at-a-time) experimentation.

- How designed experiments overcome the limitations of OATs and are a more effective and efficient way to characterize and improve processes and products.

Lesson 2 | DOE Terminology

- An explanation of the key terms used in designed experiments.

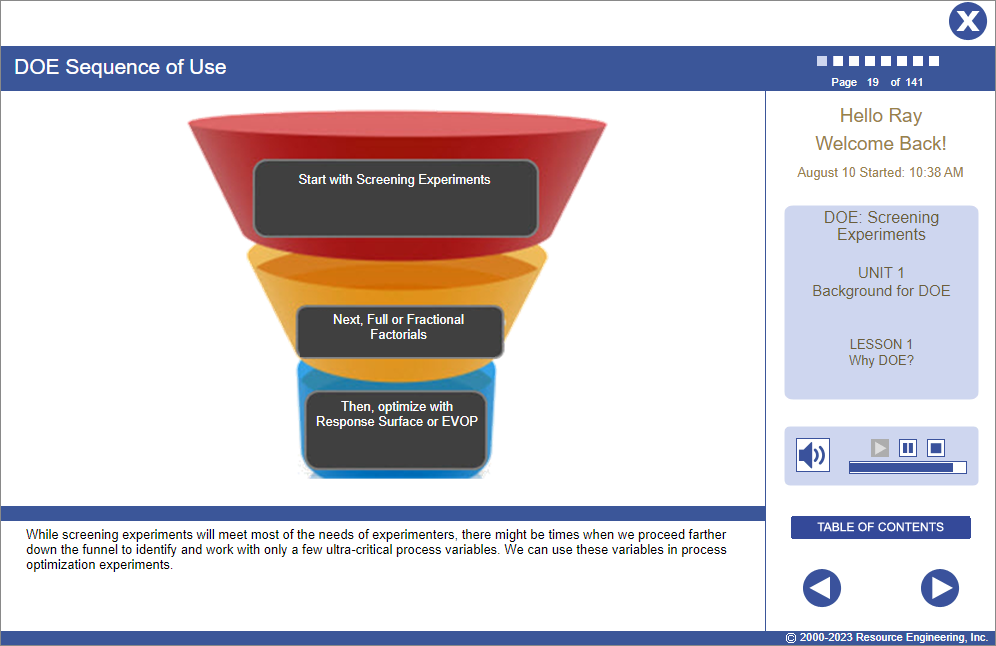

Lesson 3 | Types of Designed Experiments

- Full Factorials

- Fractional Factorials

- Screening Experiments

- Response Surface Analysis

- EVOP

- Mixture Experiments

Lesson 4 | Tests of Significance

- Alpha and Beta Risks

- Degrees of Freedom

- Hypothesis Tests

- t-Tests

- F-Tests

Lesson 5 | Setting Up a Designed Experiment

- Design & Communicate the Objective

- Define the Process

- Select a Response and Measurement System

- Select Factors to be Studied

- Select the Experimental Design

- Set Factor Levels

- Final Design Considerations

Unit 1 Challenge

- An assessment of the learner’s progress in this unit.

Unit 2 Plackett-Burman Experiments

Lesson 1 | Plackett-Burman Matrices

- The derivation of Plackett-Burman designs.

- Types of Plackett-Burman matrices.

- Ways to determine the experimental error.

- Techniques for analyzing experimental results.

Lesson 2 | Calculating Statistical Significance

- Multiple techniques for testing the statistical significance of factor effects.

- Using graphical techniques to analyze responses and interactions.

Lesson 3 | Calculating a Prediction Equation

- Developing a prediction equation using factor effects.

- Using the prediction equation to optimize the process or product.

Lesson 4 | Analyzing for Effect on Variation

- How to analyze variation as a response.

- Creating a scree diagram to graphically analyze factor effects on variation.

Lesson 5 | When Bad Things Happen to Good Experiments

- The need for good planning to prevent problems.

- Some techniques for salvaging an experiment if data are lost or suspect.

Unit 2 Challenge

- An assessment of the learner’s progress in this unit.

Unit 3 Taguchi Techniques

Lesson 1 | Taguchi Concepts

- The concept of robustness.

- The Taguchi Loss Function.

- Signal to noise ratios.

Lesson 2 | Taguchi Matrices

- Taguchi designs for two-level experiments.

- Use of Taguchi Interaction Tables.

Lesson 3 | Taguchi Experimental Analysis

- Multiple techniques for testing the statistical significance of factor effects.

- Using graphical techniques to analyze responses and interactions.

Lesson 4 | Determining Where to Set Factors

- Developing a prediction equation.

- Use the mean, signal to noise ratio, and variation effects to determine where to set factors.

Lesson 5 | When Bad Things Happen to Good Experiments

- The need for good planning to prevent problems.

- Some techniques for salvaging an experiment if data are lost or suspect.

Unit 3 Challenge

- An assessment of the learner’s progress in this unit.

4.4 out of 5 stars

Comments from Learners About This Course

- Excellent content.

- This Course is having real significance in learning for me. I have gained the real meaning of the statistics.

- Really full of knowledge.

You may also be interested in…

- 8D Problem-Solving – Step-by-step training in how to work on a problem-solving team follow the 8D methodology including tools and techniques that are used in each step.

- DMAIC Basics – Web-based training on how to solve problems using the DMAIC (Define-Measure-Analyze-Improve-Control) process.

- Root Cause Analysis with Corrective Action – Leads the learner through a four-step process to get to the root cause (source) of problems to eliminated problems for good.