Course Information

Gage Training

Learners will be able to:

- Use good measurement practices including basic GD&T concepts.

- Take accurate measures using common dimensional hand gages.

- Avoid common measuring misapplications and complications.

About This Course

Metrology and gage techniques used to be learned on the job. But as measuring equipment (even micrometers and calipers) becomes more discriminating and dimensional requirements tighter more formal metrology training is necessary.

Gage Training provides metrology, gage, and GD&T training designed for operators and technicians who use dimensional gages in their jobs to make measurements. Gage Training starts with basic dimensional metrology terminology, covers the importance of measurement standards and the difference between precision and accuracy. Next, the learner is introduced to geometric dimensioning and tolerancing (GD&T) and the fundamentals of surface finishes. Gage Training also covers how to take measurements with the most frequently used instruments including calipers, micrometers, height and depth gages, fixed gages, and gage blocks and surface plates and helps the learner understand the best way to measure various types of dimensions such as roundness and hole position.

- Basic math skills.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

Unit 1 | Gage Primer

The purpose of this unit is to develop a fundamental understanding of basic gaging concepts. The rest of the training program builds on these concepts. Upon completion of this unit you will be able to:

- Describe the purpose of measuring and the importance of precise and accurate measurements.

- Define key metrology terms.

- Explain the source of measurement standards and why they are so important.

- Read and interpret basic engineering drawing symbols.

- Understand GD&T terminology and symbols.

- Identify and classify flaws in the finish of a surface.

- Use basic geometry to describe part dimensions.

Unit 2 | Using Gages

In this unit you will learn the proper way to use a variety of dimensional measurement instruments. Upon completion of this unit you will be able to:

- Use calipers, vernier calipers, micrometers, and vernier micrometers and interpret readings taken with those instruments.

- Measure parts with both height and depth gages.

- Use fixed limit gages and describe the advantages and disadvantages of them.

- Perform measurements with comparative length devices such as test indicators and dial indicators.

- Use gage blocks for establishing dimensional standards as well as describe their qualities and grades.

- Explain the purpose and qualities of surface plates.

Unit 3 | Gaging Applications

In this unit you will learn how to select the best gage to use for particular measuring situations. Upon completion of this unit you will be able to:

- Specify the best gage to use for a variety of different measuring applications.

- Identify the best way to measure linearity, roundness, and circularity.

- Make sure you don’t make any of the most common measuring mistakes.

- Design a measurement process that eliminates or reduces potential measuring complications.

- Properly care for and maintain gages and measuring instruments.

Course Outline

Unit 1 – Gage Primer

Lesson 1 – Why Measure?

- Understand the three main reasons why parts are measured.

- Explain the five critical aspects of measuring.

Lesson 2 – Language of Measurement

- Use the language of dimensional measurement.

- Convert English to SI (metric) units of measure and SI to English units.

- Understand basic terminology used on drawings and blueprint.

Lesson 3 – Measurement Standards

- Explain the role of standards in the dimensional measurement field.

- Follow the traceability trail of calibration standards.

Lesson 4 – Precision and Accuracy

- Explain common sources of measurement error.

- Understand the impact of the five categories of measurement error: accuracy, repeatability, reproducibility, stability, and linearity.

Lesson 5 – Datums

- Use a datum to locate the position of part features.

- Identify datum planes, datum points, and datum axis.

Lesson 6 – Introduction to GD&T

- Explain the differences between coordinate tolerancing and geometric dimensioning and tolerancing.

- Interpret feature control frames.

- Use the 14 geometric characteristic controls.

- Identify GD&T modifying symbols.

Lesson 7 – Surface Finishes

- Characterize the finish of a surface.

- Identify the five most common types of surface deviations.

- Use surface symbols to communicate machining instructions.

Lesson 8 – Math for Measuring

- Add and subtract fractions.

- Convert fractions to decimals.

- Calculate the perimeter and area of rectangular shapes and the circumference and area of circular shapes.

Unit Test Challenge

- An assessment of the learner’s progress in this unit.

Unit 2 – Using Gages

Lesson 1 – Types of Gages

- Explain the differences between direct and transfer measurement gages.

- Identify the line of measurement.

- Apply the 10-times rule of measurement.

Lesson 2 – Calipers

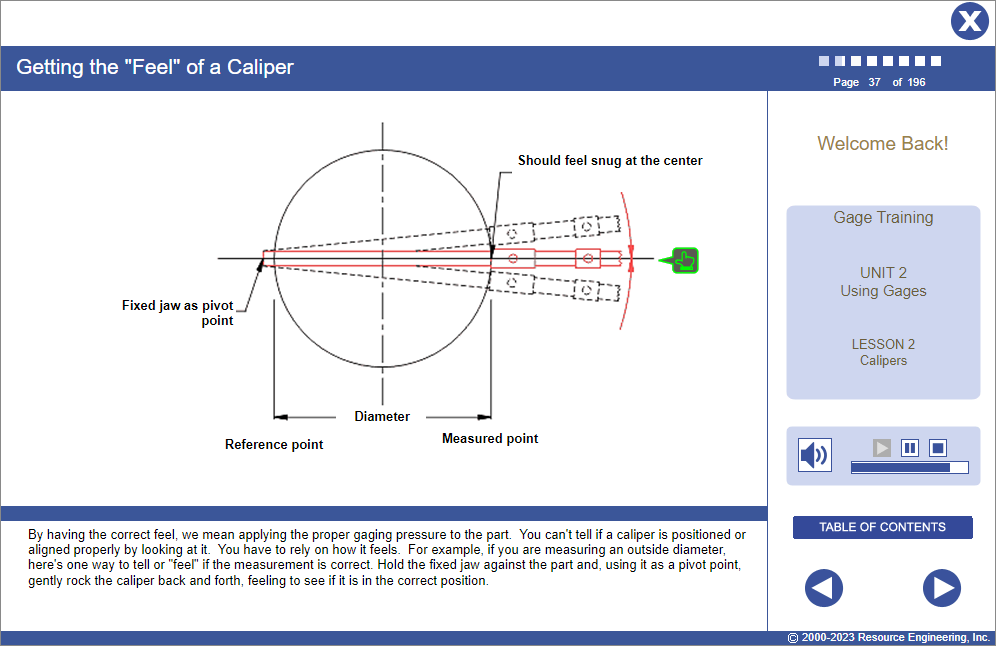

- Use a vernier scale.

- Use a caliper to take measurements.

- Explain the pros and cons of vernier, dial, and digital calipers.

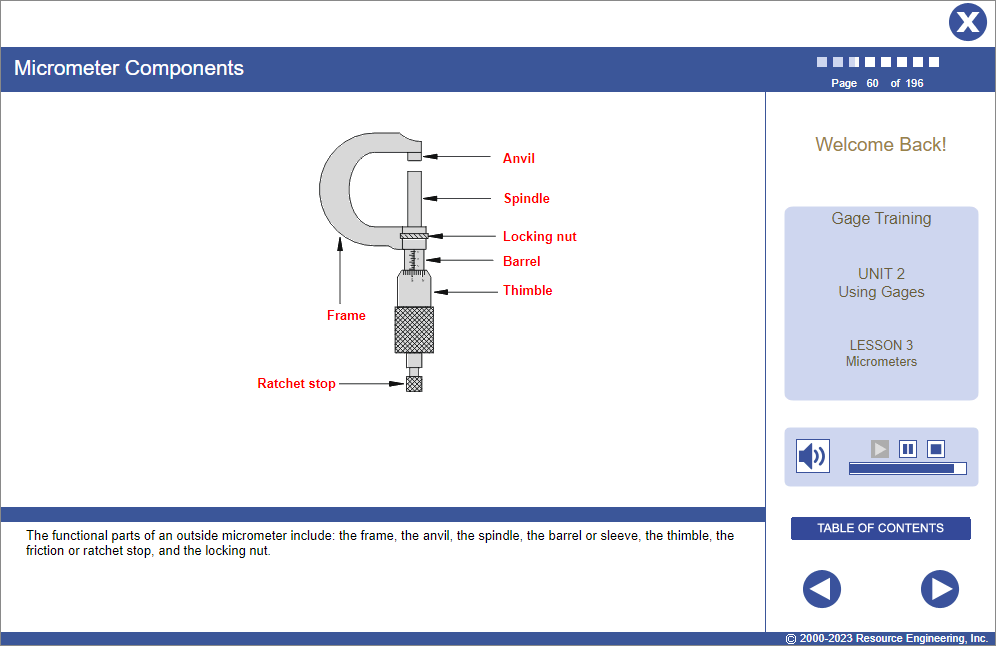

Lesson 3 – Micrometers

- Use a micrometer to take measurements.

- Read precision micrometer scales.

- Identify applications for inside and outside micrometers.

Lesson 4 – Height and Depth Gages

- Use height gages with a surface plate to take direct or comparative measurements.

- Identify height gage accessories used for specialty measuring applications.

- Use depth gages to measure the depth of features.

Lesson 5 – Fixed Gages

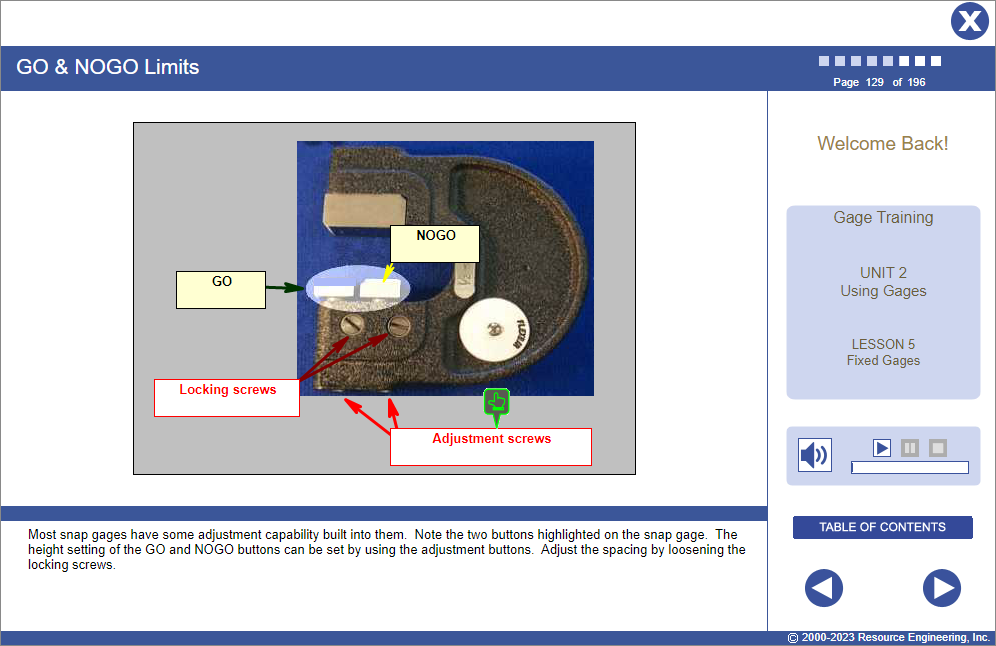

- Explain the pros and cons of fixed and variable gages.

- Identify measurement applications for fixed gages.

Lesson 6 – Test Indicators and Dial Indicators

- Use both test indicators and dial/digital indicator for comparative length measurements.

- Select indicator contact points types and test stands to specific measurement applications.

Lesson 7 – Gage Blocks and Surface Plates

- Wring and stack gage blocks.

- Use gage blocks to calibrate variable gages, check the validity of fixed limit ages, and to set comparative-length indicators.

- Use gage blocks with surface plates to make comparative measurements.

Unit Test Challenge

- An assessment of the learner’s progress in this unit.

Unit 3 – Gaging Applications

Lesson 1 – Application Overview

- Understand that some dimensional instruments are appropriate and some are not for a specific measuring application.

- Realize that there are common errors and misapplications in measuring and that they can be avoided.

Lesson 2 – Linear Measurements

- Select the appropriate type of gages for common linear measurement applications.

- Measure the position of a hole.

- Measure the differential height between two lands.

Lesson 3 – Roundness and Circularity

- Use two-point contact gages to measure out-of-roundness.

- Recognize limitations of two-point contact gages for shapes that are oval, egg-shaped, irregular or lobed.

- Be exposed to three-point contact gages and sophisticated gages to measure out-of-roundness.

Lesson 4 – Common Misapplications

- 12 common measuring mistakes and misapplications.

- What to look out for and how to prevent these mistakes from happening.

Lesson 5 – Measuring Complications

- 10 systemic problems that can lead to measuring complications.

- An exploration of why each complication may occur with suggested remedies to combat the complication and make the system more robust.

Lesson 6 – Care of Gages

- Apply universal practices to take care of gages.

- Review tips for cleaning and caring for specific instruments.

Unit Test Challenge

- An assessment of the learner’s progress in this unit.

4.6 out of 5 stars

Comments from Learners About This Course

- Good intro course to Gages and common use.

- Thorough, but basic enough for a beginner to understand.

- This course gave me a good look into the field of gaging and measuring and will be a great help within my day to day duties.

You may also be interested in…

- Measurement Systems Analysis – Comprehensive training in how to statistically measure the accuracy and reliability of measurement systems.