Course Information

Introduction to AIAG-VDA FMEAs Training

Learners will be able to:

- Describe the steps for conducting an FMEA using the AIAG-VDA FMEA methodology.

- Use the Five T’s to ensure an effective team start-up.

- Identify best practices for conducting FMEAs.

About This Course

Failure Mode and Effects Analysis (FMEA) techniques have been used for over 70 (yes, SEVENTY!) years. In recent years, the use of FMEAs has gained popularity as a quality improvement tool. Most industries are now using FMEA techniques as part of their risk assessment and risk mitigation strategies. Unlike many quality improvement tools, FMEAs do not require complicated statistics. FMEA studies can yield significant savings for a company as well as reduce potential risks and associated liabilities of a product or process that does not perform as intended.

In 2019, AIAG (Automotive Industry Action Group, www.aiag.org) and VDA (Verband der Automobilindustrie, www.vda.de), two of the leading automotive trade associations, unveiled a major revision to FMEA methodology with the release of the AIAG-VDA FMEA Handbook.

This online training introduces learners to the 2019 AIAG-VDA FMEA Process. Participants will complete the course with an understanding of the new FMEA methodology including the 7-step FMEA process and Action Priority Tables. This course is ideal for senior managers who need to understand the concepts and terminology of AIAG-VDA FMEAs, but who will not be actually participating on an FMEA team. For practitioners participating on FMEA teams, we offer more in-depth training in our AIAG-VDA Process-FMEAs and AIAG-VDA Design-FMEAs courses.

IMPORTANT NOTE: While the Introduction to AIAG-VDA FMEAs is in line with the AIAG-VDA FMEA Handbook, it is not intended as a replacement for thorough training or the source Handbook. We recommend that this course be used in conjunction with the official Handbook.

- None

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Understand the systematic approach that FMEAs take to identify and reduce risks.

- Describe the differences between Design and Process FMEAs.

- Learn the steps for conducting an AIAG-VDA FMEA at a conceptual level.

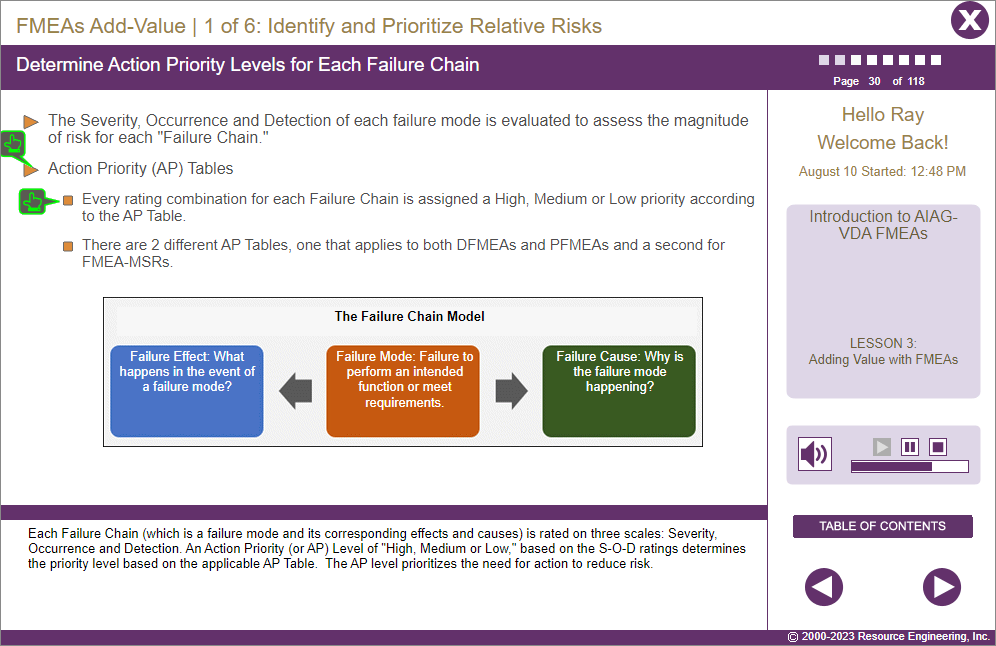

- Describe the “Failure Chain” concept in FMEAs.

- Understand how evaluation criteria is used to rate the levels of Severity, Occurrence and Detection.

- Become aware of how Action Priority Tables establish Action Priority (AP) levels for potential risks.

- Know what the Five T’s are and how they are used to ensure successful FMEA team start-ups.

- Define the six best practices for conducting FMEAs.

Course Outline

Lesson 1 | What is an FMEA?

- Know what an FMEA is and why an FMEA is used.

- Understand how an FMEA is conducted on a conceptual basis.

Lesson 2 | Purposes of FMEAs

- Understand how the systematic FMEA approach gets us to dig into the details of the design or process under study to identify potential risks.

- Realize how an FMEA helps identify risks, prioritizes the risks relative to one another and focuses efforts on an action plan to reduce the risks.

Lesson 3 | Adding Value with FMEAs

- To gain an appreciation for how FMEAs add value to the organization.

Lesson 4 | Types of FMEAs

- Explain the differences between a DFMEA (Design-FMEA) and a PFMEA (Process-FMEA).

- Recognize that alternative types of FMEAs do exist and understand the reasons for their use as well as the differences in the tactics used to conduct them.

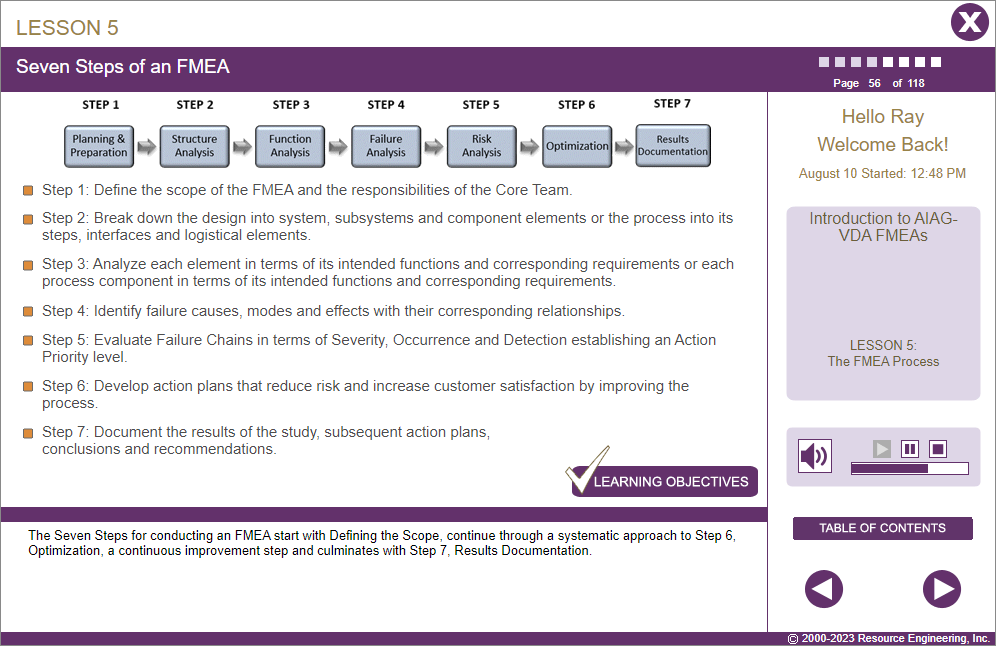

Lesson 5 | The FMEA Process

- Be familiar with the 7 steps used to conduct an FMEA.

- Understand how Failure Chains work.

- Understand how evaluation criteria is used to rate the levels of Severity, Occurrence and Detection.

- Become aware of how Action Priority Tables establish Action Priority (AP) levels for potential risks.

Lesson 6 | Assembling an FMEA Team

- Understand how to assemble an effective Core Team for conducting FMEAs.

- Recognize how an Extended Team complements the Core Team

- Appreciate the role of Subject Matter Experts when conducting an FMEA.

- Be aware of how the Five T’s are used to ensure successful team start-ups.

Lesson 7 | Best Practices for Conducting FMEAs

- To become familiar with six (of the) best practices for conducting FMEAs.

Challenge

- An assessment of the learner’s progress in this course.

4.4 out of 5 stars

Comments from Learners About This Course

- Very easy to follow and well explained. Presentation and supporting material are quite useful.

- Thorough coverage for the scope of the course.

- Excellent overview.

You may also be interested in…

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.

- 8D Problem-Solving – Step-by-step training on how to work on a problem-solving team following the 8D methodology including tools and techniques that are used in each step.

- Root Cause Analysis with Corrective Action – Leads the learner through a four-step process to get to the root cause (source) of problems to eliminate problems for good.