Course Information

Lean Mindset Training

Learners will be able to:

- List the benefits of streamlining the entire value stream.

- Describe how lean techniques can be applied to all functions of a business as well as manufacturing.

- Explain the linkage between Lean and Six Sigma.

About This Course

Simply put, lean organizations are customer-focused. They reduce waste in their value streams by improving workflows and then by subsequently improving the physical layout of their facilities. Process capacity is managed and actually increased by reducing set-up times, improving quality, and ensuring equipment works when it is counted upon to work.

Successful implementation of a lean initiative requires a mindset that focuses on the customer and sees waste as a cost not to be tolerated by the organization. While this makes sense many aspects of lean are counter-intuitive to traditional manufacturing thinking and practices.

This course explores the mindset needed to launch and sustain a successful Lean initiative. The most productive lean efforts extend beyond manufacturing to the entire organization; it is everyone’s job to drive waste out of the organization. The Lean Mindset Online Training describes how different functions in a business can apply Lean Manufacturing techniques to streamline the value stream. Learners will also be introduced to lean terminology so the organization has a common lean language.

- Understanding and application of the principles of the 5S’s such as The 5S’s: Workplace Organization or equivalent.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Explain why it is important that lean not just be used in manufacturing, but throughout the organization.

- Describe the benefits of lean in the office, maintenance, R&D, and Sales.

- Define key lean terms and know how to apply lean terminology.

- Understand the purpose of streamlining the value stream.

- Describe the steps to streamline a workflow.

- Identify the key characteristics of a lean value stream.

- Compare and contrast the difference between a macro and micro workflow.

- Describe the impact of a bottleneck on a process.

- Explain what “If it’s not broke, fix it anyway.” means.

- Identify activities that can help you learn from others outside of your organization.

- Describe the benefits of cross-training.

Course Outline

Lesson 1 | Why Lean?

- Be customer focused: Be on-time, responsive, flexible, and fast.

- Simplify and standardize workflows: Mimic continuous flow, minimize WIP, use visible measures.

- Manage capacity: Increase process uptime, reduce set-up times, find “lost” capacity.

- Eliminate waste: Identify non-value adding activities, then modify, combine, or eliminate those tasks.

- JiT: Not too early and never late; not just-in-case inventory but just-in-time production and delivery; products must always be made right the first time; equipment must always work when needed.

Lesson 2 | Lean Terminology

- Terms

- Tools

- Techniques

Lesson 3 | Streamlining the Value Stream

- Identify process goals.

- Collect and analyze process data.

- Create a macro-facility workflow to determine how to minimize high volume travel distances.

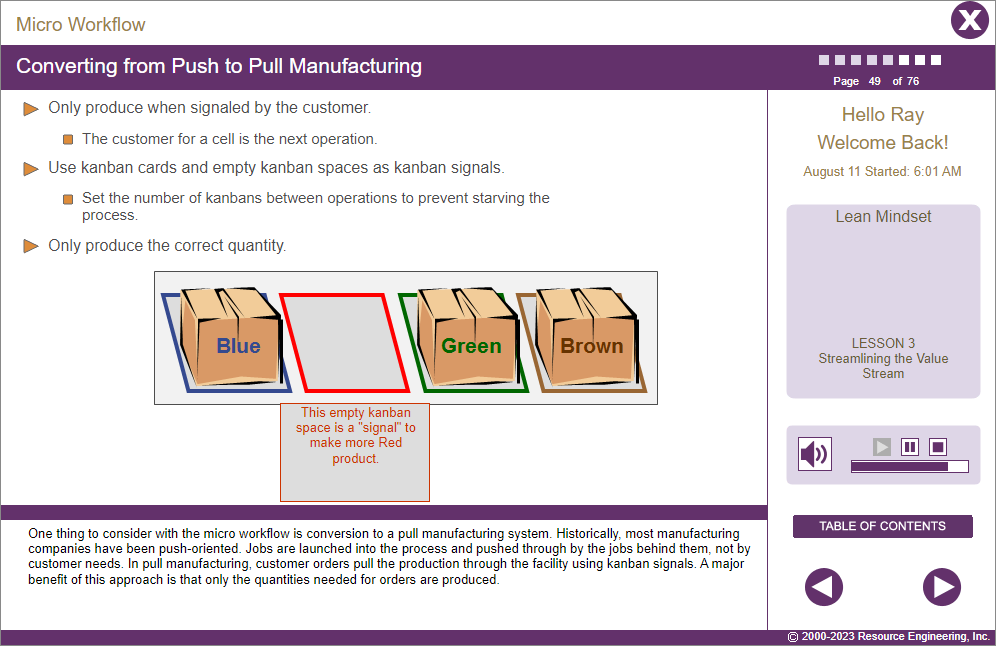

- Conduct a micro-process workflow to apply cellular concepts, identify and remove bottlenecks, and move to pull manufacturing with kanbans.

Lesson 4 | Continuous Improvement

- Fight NIH (not-invented-here) attitudes and leverage successes.

- Use kaizen events for rapid, targeted improvements to achieve the future state.

- Use a standardized Problem-Solving Model (e.g. DMAIC or 8D).

- Begin an employee idea system.

Challenge

- An assessment of the learner’s progress in this course.

4.6 out of 5 stars

Comments from Learners About This Course

- Great information!!

You may also be interested in…

- Lean Manufacturing – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a manufacturing environment.

- Lean for Business Processes – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a transaction-based/non-manufacturing business or job function.