Course Information

Lean Process Layouts Training

Learners will be able to:

- Use data to create effective and efficient process layouts.

- Describe the concepts and benefits of common process layout configurations.

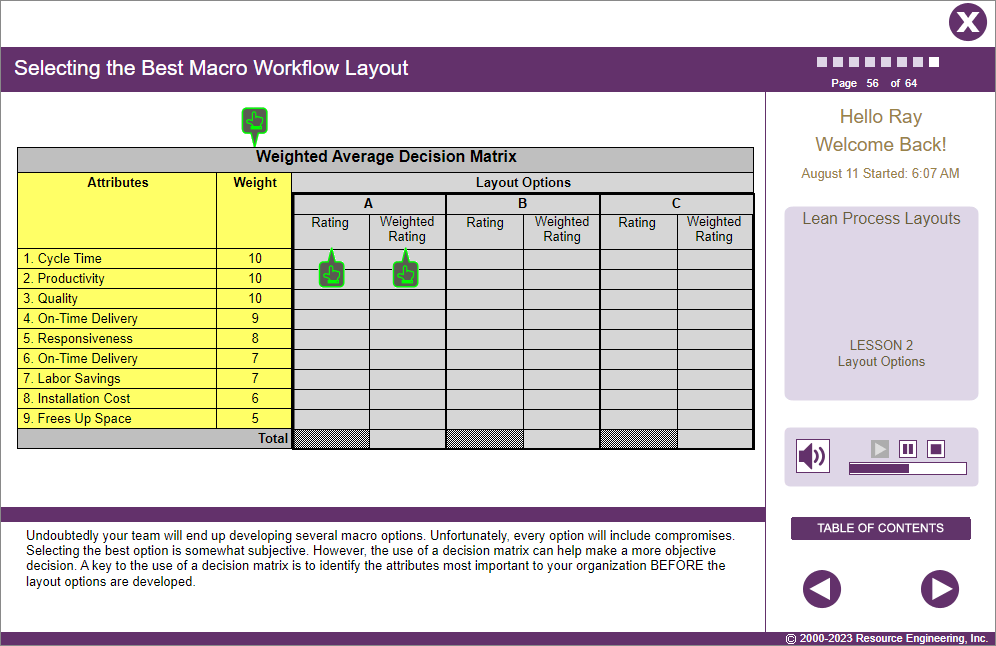

- Select and implement the best layout option for the process.

About This Course

What are Lean Manufacturing Process Layouts?

Manufacturing process layouts are an important focus in Lean organizations because they are often full of inefficiencies that lead to wasted time, effort and materials. The first step in rethinking a manufacturing layout is collecting data about the existing process. Information such as machine load, takt time, equipment reliability, set-up time, yields, and staffing requirements are necessary inputs for redesigning process layouts.

With data on the existing process, new layouts can be considered in order to minimize cycle time and travel distance and simulate a continuous flow process. Each scenario will present unique challenges (process flow, physical constraints and support systems) that will need to be considered as the ideal process flow is developed.

Lean Manufacturing Process Layout Online Training

This course explores sources and formats for collecting and analyzing data for lean efforts and shows how to use that data to design process flow patterns and physical layout options leading to lean practices.

- Understanding of terminology and philosophy of Lean Manufacturing such as Overview of Lean or equivalent.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe the purpose of setting up work cells based on product families.

- Explain the purpose of a macro workflow and why it should be developed before micro workflows are determined.

- Identify major issues to consider when laying out a macro workflow.

- List factors that must be considered when establishing a micro workflow.

Course Outline

Lesson 1 | Data Drives Lean

- Focus efforts on projects that lead to tangible savings.

- Calculation techniques to generate data include: Time studies, equipment loading, TAKT time, staffing requirements, process yields, and COQ.

- Sample Worksheets covered include: Lean Project Summary; Cell Target Worksheet; Data Collection Form for Basic Equipment and Utility Parameters; Value-Adding Analysis Worksheet; Process Change-Over/Setup Worksheet; Set-Up Reduction Worksheet; and Lot Size Worksheet.

Lesson 2 | Layout Options

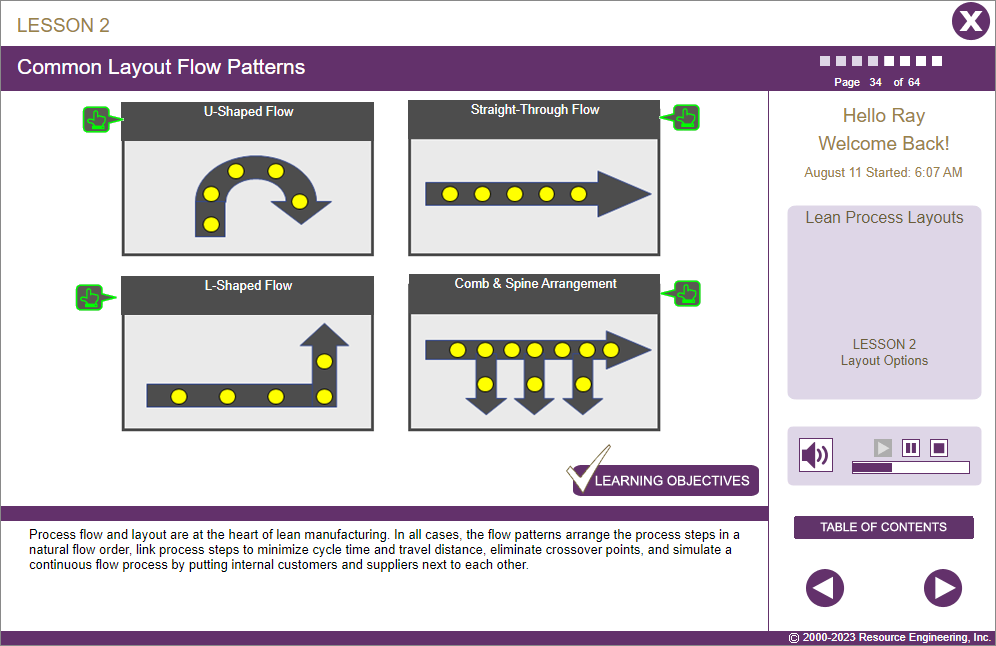

- Improved layouts are about moving cubic feet (not numbers of items), eliminating crossover points, arranging the process in the natural flow order; linking processes to minimize time and distance; moving equipment together to simulate a continuous process flow; and putting internal customers and suppliers next to each other.

- Be careful to identify anchors or monuments; do not move them.

- Typical layout options are explored.

Challenge

- An assessment of the learner’s progress in this course.

4.8 out of 5 stars

You may also be interested in…

- Lean Manufacturing – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a manufacturing environment.

- TPM Basics – Focused training on what TPM is and how it can be used to improve the reliability of equipment in a manufacturing environment.