Course Information

Lean for Support Processes Training

Learners will be able to:

- Apply Lean practices to office/business support processes.

- Translate the Seven Wastes to apply to office/business support processes.

- Use Lean techniques to reduce waste and streamline office systems.

About This Course

How can Lean Concepts Apply in Non-Manufacturing?

Lean manufacturing has been used both conceptually and in practice to identify and eliminate waste in manufacturing operations for years. Can Lean Manufacturing principles and practices be applied to business processes? Of course! Lean is all about getting waste out of processes and waste isn’t just something that happens in manufacturing. Non-manufacturing processes have hand-offs, disconnects, incomplete communications and rework loops. Office and support processes are often ripe for streamlining and many of the same improvement tools such as process mapping, the 5S’s, and error-proofing can be used to achieve significant efficiencies. Lean process measures can then be put into place to monitor the improvement results, hold the gains and identify new opportunities for improvement.

Lean for Support Processes Online Training

Lean for Support Processes online training is designed specifically for those working in business processes and transactional environments. The course begins with explanations and examples of the Seven Wastes in “office-friendly” terms. Process mapping techniques are coupled with process streamlining methods to demonstrate how value streams can be configured to be more effective. The course adds 5S, error-proofing and TPM techniques to the Lean Business Process arsenal and wraps up with descriptions of measures that can be used to sustain and expand the Lean initiative. We also have a Lean Manufacturing course for manufacturing environments.

- An understanding and application of the principles of the 5S’s such as Introduction to the 5S’s or equivalent.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Understand the Seven Wastes and be able to actively support efforts to reduce them.

- Recognize value-added from the customer’s perspective.

- Use Brown-Paper Flowcharts, Workflow Diagrams and Value Stream Maps to document current processes.

- “Question” workflows to identify non-value-adding activities and tasks.

- Develop a plan to simplify and streamline workflows.

- Support a 5S effort in their work area.

- Understand the power of error-proofing to prevent future problems.

- Assist a Support Process TPM effort.

- Be able to track macro measures of the Lean initiative.

Course Outline

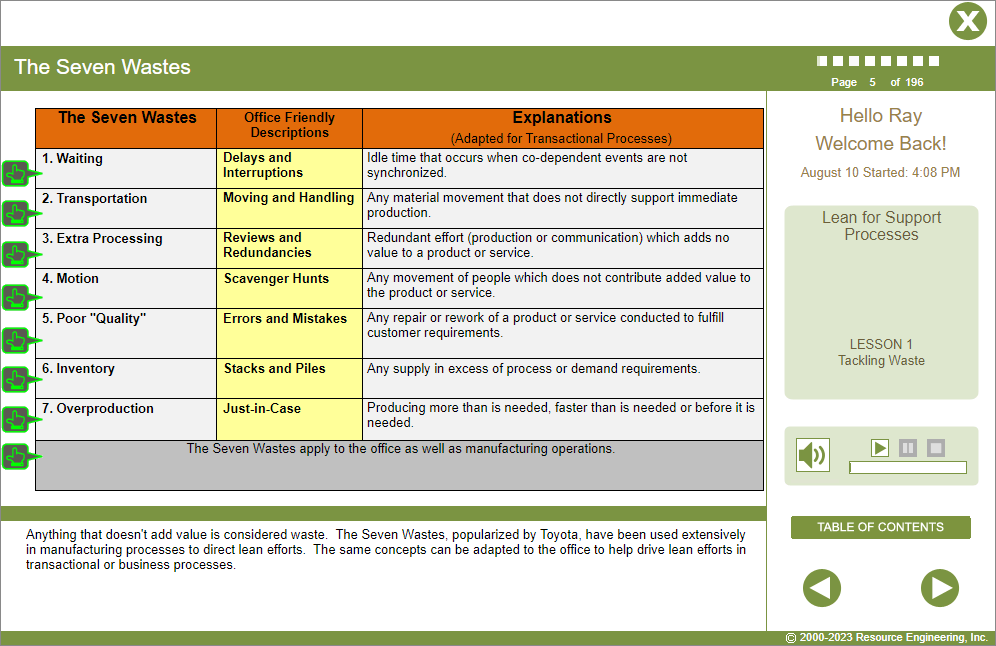

Lesson 1 | Tackling Waste

- Identify the seven wastes.

- Explain value-adding versus non-value adding.

- Define value from customer’s perspectives.

- Briefly describe how each of the seven wastes detracts value from a process.

Lesson 2 | Process Mapping

- Define the bounds of a workflow.

- Use a variety of process (workflow) mapping techniques.

- Identity hand-offs, disconnects, incomplete communication and rework loops as non-value-adding components (or waste.)

- Plan improvements to workflows.

- Consider a move from batch processing to continuous (or one-piece) flow.

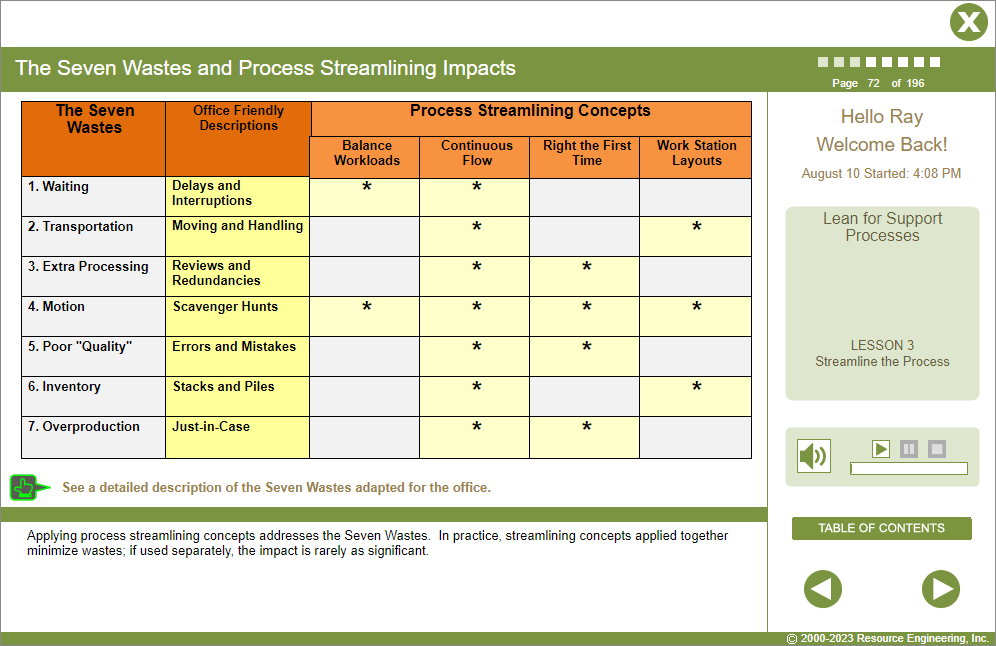

Lesson 3 | Streamline the Process

- Know what Takt Time means.

- Identify process bottlenecks.

- Calculate Process Cycle Efficiency.

- Understand how to balance workloads within a process workflow.

- Calculate First Pass Yield.

- Be familiar with workflow and workstation layout considerations.

Lesson 4 | 5S’s in the Office

- Identify each of the 5S’s.

- Know how to clear clutter from a work area.

- Explain the rationale for selecting effective designated storage locations.

- Understand how to maintain the work area’s appearance and use preventive measures to keep it clean.

- Describe what it means to standardize and why standardization is important.

- Know how to use audits to sustain workplace organization and to prevent backsliding.

Lesson 5 | Error-Proofing Overview

- Be aware of common error-proofing techniques.

- Comprehend the Transaction Model (consisting of the server-side and customer-side.)

- Know how to use basic root cause analysis tools.

Lesson 6 | TPM for Support Processes

- Be aware of TPM’s impact on the Seven Wastes.

- Recognize TPM’s influence on reliability and uptime of office support systems.

- Begin measuring Overall Equipment Effectiveness.

Lesson 7 | Lean Support Process Measures

- Measure Lean efforts by tracking Process Cycle Efficiency trends.

- Create a Balanced Scorecard to track waste reduction.

- Audit 5S activities to maintain workplace organization momentum.

- Monitor uptime, throughput rates and yields using Overall Equipment Effectiveness.

- Develop two-dimensional surveys to gather meaningful customer feedback.

Challenge

- An assessment of the learner’s progress in this course.

4.7 out of 5 stars

Comments from Learners About This Course

- Course is very well designed, organized and is crisp to the point.

- Excellent Course. It has everything for a lean journey.

- Very beneficial for my role.

- Very good, excellent presentation.

You may also be interested in…

- The 5S’s: Workplace Organization – Comprehensive training in the concepts and application of the 5S’s (Sort, Set in Order, Shine, Standardize and Sustain) and how to apply these techniques on the job.

- 8D Problem-Solving – Step-by-step training in how to work on a problem-solving team follow the 8D methodology including tools and techniques that are used in each step.