Course Information

Managing Calibration Programs Training

Learners will be able to:

- Explain the impact of instrument calibration on product and process quality.

- Develop and implement a calibration management plan.

- Reduce sources of measurement error.

About This Course

Why is a program that Manages Calibration Systems necessary?

- A measurement device that doesn’t read accurately and repeatably or is no longer in calibration compromises the integrity of the quality of your product and can unknowingly lead to the production of nonconforming parts.

- We need to “trust” measuring devices to effectively and efficiently produce product. If the gages and instruments used are not controlled and calibrated, there is no way of knowing what the true output of a process really is!

- Based on measurements that are taken during manufacturing, an organization may think that it is producing good parts only to find out that the parts are seriously defective or out-of-tolerance because the measuring device used is inaccurate, out-of-calibration, or not stable. When that happens, it is no difference than using a “rubber ruler” for measuring!

The Managing Calibration Programs course will help learners learn about the importance of measurement device calibration management.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Explain the importance of calibration and management.

- Describe the primary sources of measurement error.

- Show how the calibration of a measurement device is tied to ISO standards.

- Specify requirements for measurement instrument management software, if you choose to computerize your records.

Course Outline

Lesson 1 | Formal Instrument Management

- Identify the components of a good calibration program.

- Explain why many industry standards require formal measurement device management programs.

Lesson 2 | Sources of Measurement Error

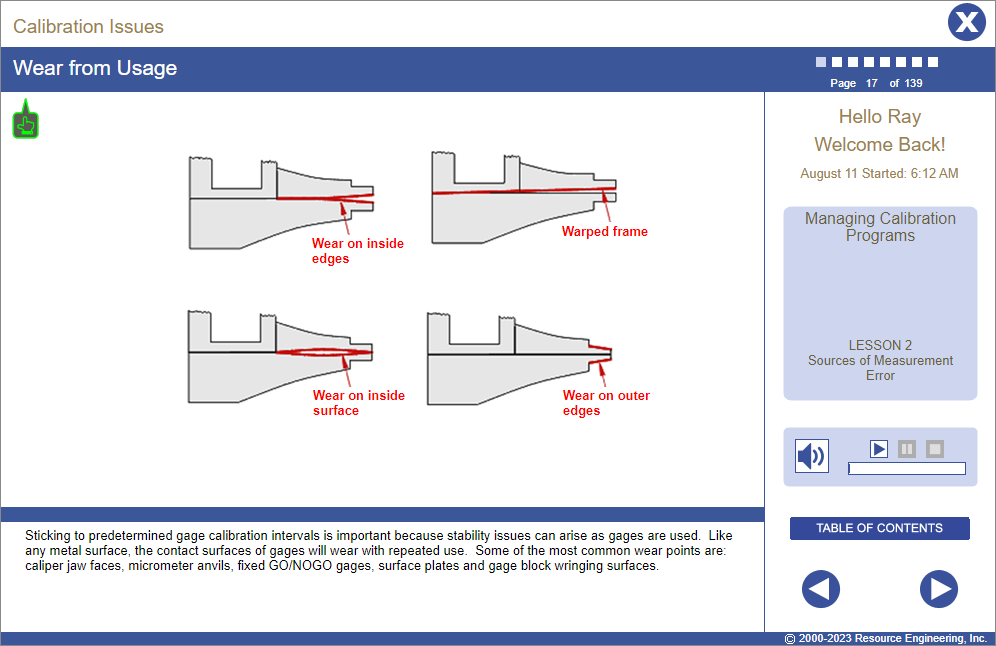

- Explain the four major categories of measurement error: calibration, usage or handling damage, errors of judgment, measurement system variation.

- Know what to do about sources of measurement error.

Lesson 3 | Calibration Practices

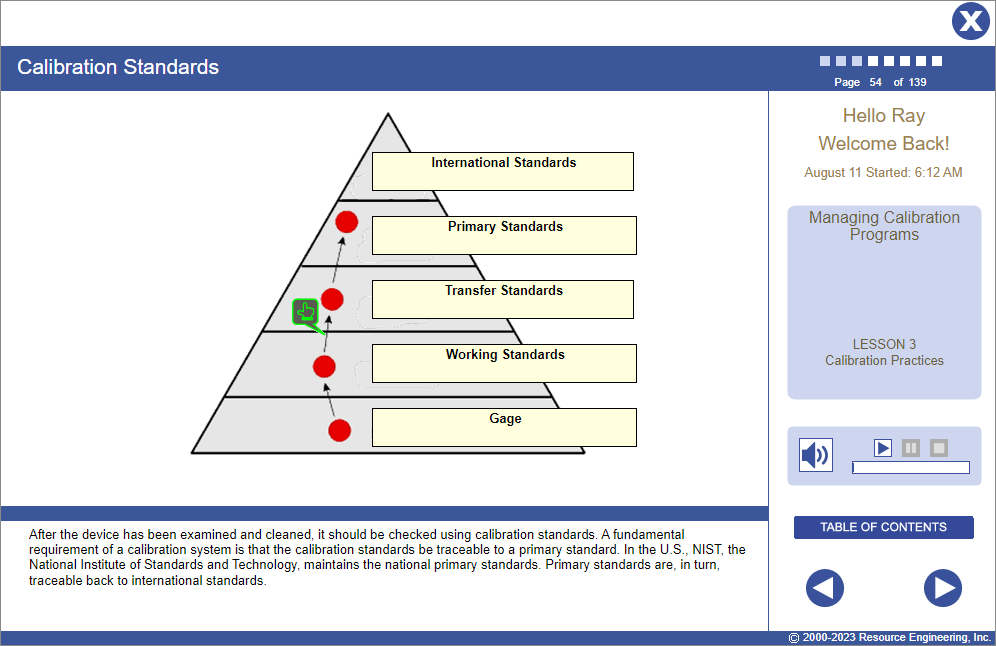

- Understand the requirements of a measurement calibration system as defined by ISO 10012.

- Establish calibration procedures to check the calibration of a measurement device.

Lesson 4 | Calibration Standards & Tools

- Understand the traceability route of measurement standard back to primary national standards and ISO.

- Select measurement standards appropriate for the measuring device.

Lesson 5 | Calibration Pitfalls

- Become familiar with the 7 most common calibration pitfalls.

- Overcome calibration pitfalls.

Lesson 6 | Records & Audits

- Establish comprehensive records needed to document the management of measurement devices.

- Develop an audit system to ensure the measurement management system is being used correctly.

Lesson 7 | Calibration Software Considerations

- Explore common options of measurement management software.

- Evaluate measurement management software to select the software program that best fits the needs of your organization.

Challenge

- An assessment of the learner’s progress in this course.

4.8 out of 5 stars

Comments from Learners About This Course

- Good course, very informative!

- Thorough and informative!

- Great content, good references and solid description details of a calibration program.

You may also be interested in…

- Gage Training – Comprehensive training in how to use a variety precision hand gages including an overview of basic measuring concepts, introductory blueprint reading, an overview of GD&T, and which gages to use when.

- Measurement Systems Analysis – Comprehensive training in how to statistically measure the accuracy and reliability of measurement systems.

- Internal Audit Training – Focused on the six steps of a clause-based internal audit process.