Course Information

Mistake-Proofing Training

Learners will be able to:

- Describe mistake-proofing effects, outcomes, and solutions.

- Use mistake-proofing techniques to eliminate process and product problems.

- Integrate mistake-proofing into the overall Quality Improvement Process.

About This Course

What is Mistake-Proofing (Poka Yoke)?

Mistakes seem to happen at the worst time. At work, just before a critical shipment, an inadvertent mistake causes the entire shipment to be rejected. Or at home, just before leaving for a long anticipated vacation, “Murphy’s Laws” intervene, and a series of seemingly unavoidable mistakes delays our departure.

Can we defeat Murphy’s Laws? Can we eliminate these costly mistakes? Probably not totally, but the use of mistaking-proofing tools and techniques will put an end to many of the repetitive, costly mistakes that rob us of time and money both at home and at work.

Mistake-Proofing is more than just incremental improvements or trying harder to do a better job. Mistake-Proofing techniques don’t just reduce the chance of making errors, but they eliminate the possibility for error altogether.

Mistake-Proofing Online Training

Mistake-Proofing online training will help put you on the path to defeating Murphy’s Laws. With Mistake-Proofing, you will not only learn a systematic way to error-proof processes and products, but you will also see a wealth of examples of mistake-proofing solutions applied to real-life recurring problems. Most people learn mistake-proofing skills by seeing examples and then stealing shamelessly to apply similar solutions to their own problems. That’s why Mistake-Proofing is loaded with lots of examples that will trigger implementation of more mistake-proofing solutions in your company. Check out Error-Proofing Support Processes if you are looking for Mistake-Proofing training in a non-manufacturing setting.

Mistake-Proofing is divided into four units. Unit 1, The Mistake-Proofing Primer provides a conceptual background and foundation for mistake-proofing efforts. Unit 2, Effects of Mistake-Proofing, covers practical mistake-proofing techniques. Tools to design and implement mistake-proofing solutions are covered in Unit 3, Mistake-Proofing Solutions. Examples of problems along with accompanying mistake-proofing solutions in a variety of settings are explored in Unit 4, Mistake-Proofing in Action.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

Unit 1 | Mistake-Proofing Primer

- Understand the goal of mistake-proofing.

- Know the language of mistake-proofing.

- Recognize mistake-proofing solutions in everyday life and use these solutions as triggers for ideas to mistake-proof your processes.

- Identify the five process input elements that exist in any process.

- Recognize why errors are made.

- See the value of improving processes so that mistakes are prevented instead of relying on inspection to find mistakes.

Unit 2 | Effects of Mistake-Proofing

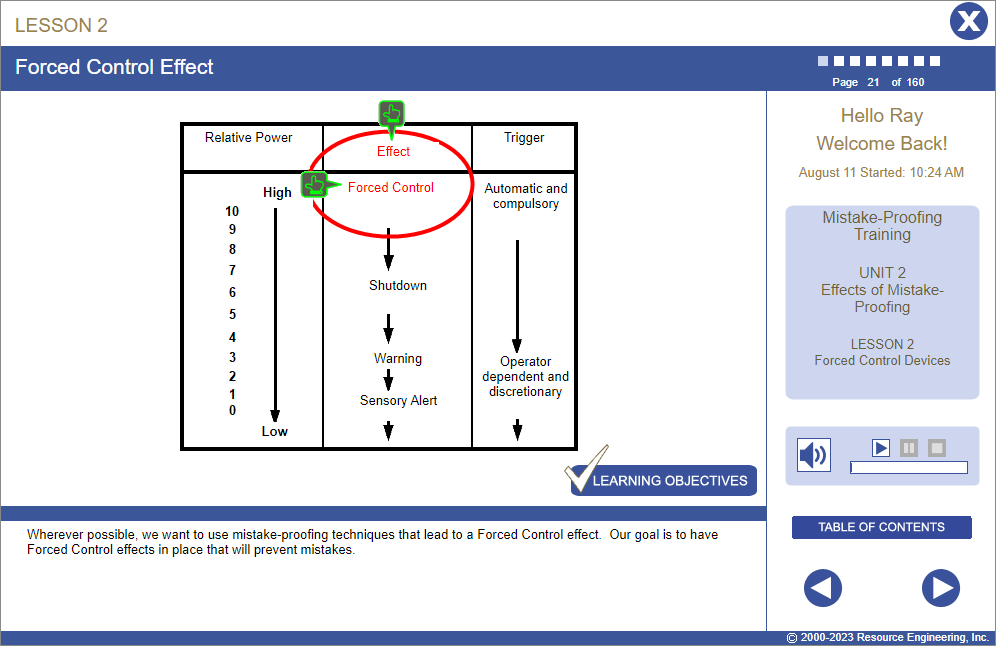

- Be able to rank the relative power of the different forms of mistake-proofing effects.

- Recognize a forced control effect. Be able to apply:

- Elimination

- Combination

- Guides

- Process control

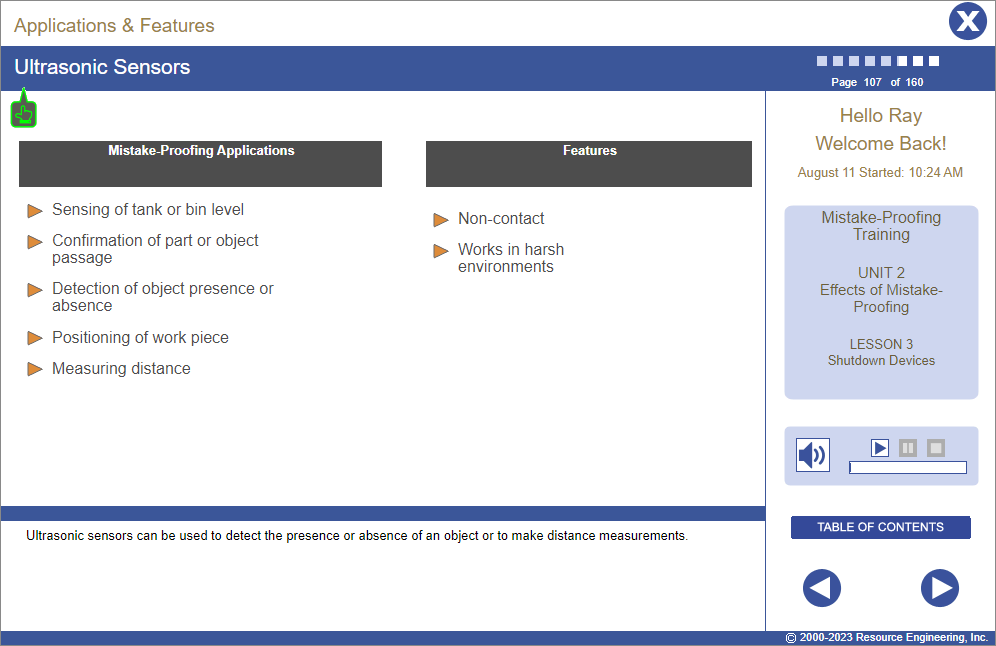

- Have an understanding of some of the types of sensors available to achieve a shutdown effect.

- Have an understanding of some of the types of devices available to create a mistake-proofing solution using a warning effect.

- Know how to apply sensory alert effects to mistake-proofing.

Unit 3 | Implementing Mistake-Proofing Solutions

- Learn to apply mistake-proofing solutions after the root cause has been found.

- Be able to evaluate whether the mistake-proofing solution is practical, feasible, and cost-effective.

- Learn how to build-in ways to assure your solution does not get overridden.

- Evaluate the robustness level of your solution.

- Become familiar with 10 improvement tools that complement the mistake-proofing process.

Unit 4 | Mistake-Proofing in Action

In this unit, recurring problems from a variety of industrial settings are explored and successful mistake-proofing solutions are shown. The problems come from the following industrial settings:

- High volume manufacturing.

- Assembly operations.

- A job shop environment.

- Process industries.

- Equipment set-up.

- In the office.

The primary objective of this Unit is to expose you to a variety of mistake-proofing solutions to help you develop your own mistake-proofing solutions.

The secondary objective is to help you think through the solution presented and then identify what type of solution has been used.

Course Outline

Unit 1 Mistake-Proofing Primer

Lesson 1 | What is Mistake-Proofing?

- Rewriting Murphy’s Laws.

- Exploring the source of mistakes.

- The mindset necessary for mistake-proofing.

Lesson 2 | Mistake-Proofing in Everyday Life

- Common examples of mistake-proofing all around us.

- Using these examples to trigger ideas at work.

Lesson 3 | Why Errors Are Made

- How process inputs create process outputs.

- Why the root causes of errors must be identified.

Lesson 4 | Inspecting vs. Mistake-Proofing

- The limitations of inspection.

- Why prevention is always more powerful than detection.

Lesson 5 | How Mistake-Proofing Works

- The language of mistake-proofing.

- The role of teams in mistake-proofing efforts.

Unit 1 Challenge

- An assessment of the learner’s progress in this unit.

Unit 2 Effects of Mistake-Proofing

Lesson 1 | Approaches to Mistake-Proofing

- Exploring the 8 forms of mistake-proofing solutions.

- Guidelines for selecting a mistake-proofing approach.

Lesson 2 | Forced Control Devices

- Delving into the four families of devices and methods used to achieve a forced control effect.

Lesson 3 | Shutdown Devices

- Examining 10 common families of sensors used to achieve a shutdown effect.

Lesson 4 | Warning Devices

- Investigating 4 families of audible alarms and 4 families of visual alarms used to achieve a warning effect.

Lesson 5 | Sensory Alert Devices

- A look at the use of color-coding, missing-in-action clues, and other aids to achieve a sensory alert effect.

Unit 2 Challenge

- An assessment of the learner’s progress in this unit.

Unit 3 Implementing Mistake-Proofing Solutions

Lesson 1 | Integrating Mistake-Proofing and Problem Solving

- How to incorporate mistake-proofing solutions into common problem-solving processes.

Lesson 2 | Practical, Feasible, and Cost Effective Solutions

- Assessment techniques for determining the practicality, feasibility, and cost-effectiveness of your mistake-proofing solutions.

Lesson 3 | How to Keep Solutions from Being Overridden

- Tips for keeping your mistake-proofing solution from being ignored or disabled.

Lesson 4 | How Robust is Your Solution?

- Assessment techniques for determining how robust your mistake-proofing solutions are.

Lesson 5 | Complementary Tools

- How to use ten continuous improvement tools to complement mistake-proofing efforts.

Unit 3 Challenge

An assessment of the learner’s progress in this unit.

Unit 4 Mistake-Proofing in Action

Lesson 1 | Mistake-Proofing in High Volume Manufacturing

- Nowhere are the benefits of mistake-proofing more evident than in high volume operations.

- 8 real-life examples of mistake-proofing solutions in a high volume environment.

Lesson 2 | Mistake-Proofing in Assembly Operations

- Mistake-proofing is a perfect tool to prevent assembly errors.

- 8 real-life examples of mistake-proofing solutions in assembly operations.

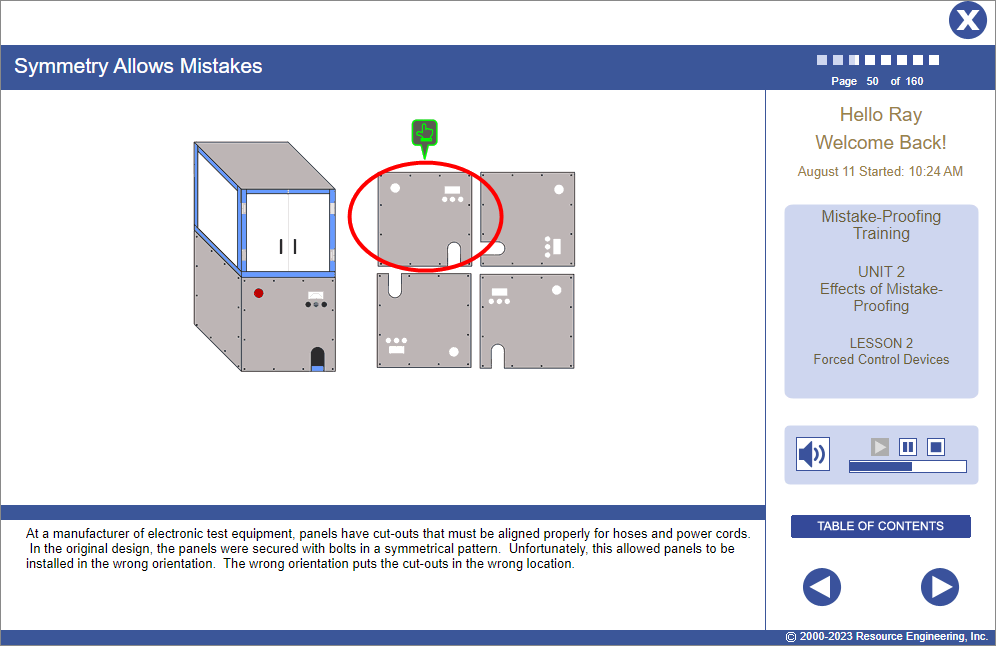

Lesson 3 | Mistake-Proofing in a Job Shop Environment

- Mistake-proofing in short-run job shops can make the difference between profitability and bankruptcy.

- 8 real-life examples of mistake-proofing solutions in a job shop environment.

Lesson 4 | Mistake-Proofing in Process Industries

- Mistake-proofing is at the core of complex chemical operations.

- 8 real-life examples of common sense mistake-proofing solutions from the process industry that can trigger ideas to simplify your operation.

Lesson 5 | Mistake-Proofing in Equipment Set-up

- Mistake-proofing is an important element of set-up reduction.

- 8 real-life examples of mistake-proofing solutions to aid equipment set-up and speed product change-overs.

Lesson 6 | Mistake-Proofing in the Office

- Mistake-proofing is not just for plant operations.

- 8 real-life examples of mistake-proofing solutions in the office.

4.6 out of 5 stars

Comments from Learners About This Course

- Good course; used what I learned already.

- Very practical.

- Nice course. Really helped me learn the different types of pokayoke.

- I really enjoyed this training – very detailed with great examples and info for further project planning.

- It helped me with determining which way to go while I’m dealing with an issue or an ongoing issue to help resolve the problem all together.

- The course did a great job at identifying and categorizing different mistake proofing methods.

- I found this course very helpful in understanding mistake-proofing. The content was explained in a clear and easy to understand manner. Many examples were reviewed to provide an understanding of the different mistake-proofing solutions.

- As someone who is working in the Automotive Industry; This course was a great insight into mistake proofing techniques, I loved and enjoyed every minute of it. I will surely be back for more courses along this line.

You may also be interested in…

- Error-Proofing Support Processes – Comprehensive online training in poka yoke/mistake-proofing techniques in non-manufacturing operations.

- 8D Problem-Solving – Step-by-step training in how to work on a problem-solving team follow the 8D methodology including tools and techniques that are used in each step.

- The Five Why’s – Focused training in how to use the Five Why’s technique to get to the root cause of problems.