Course Information

Process Capability Basics Training

Learners will be able to:

- Explain what is meant by a capable process.

- Differentiate between in-specification and capable.

- Describe key process capability measures and interpret what they say about the process.

About This Course

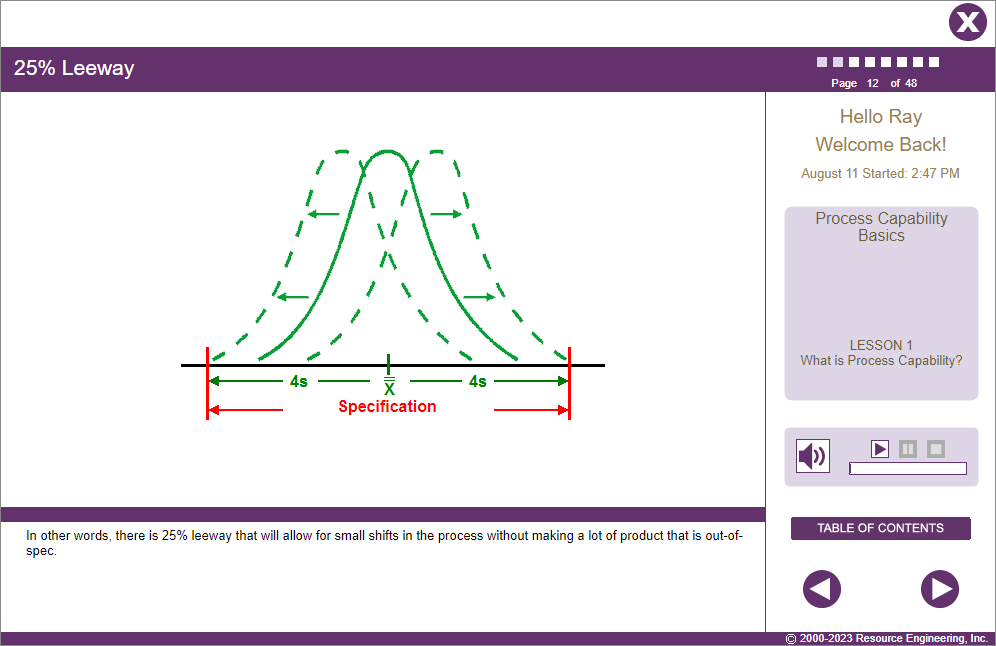

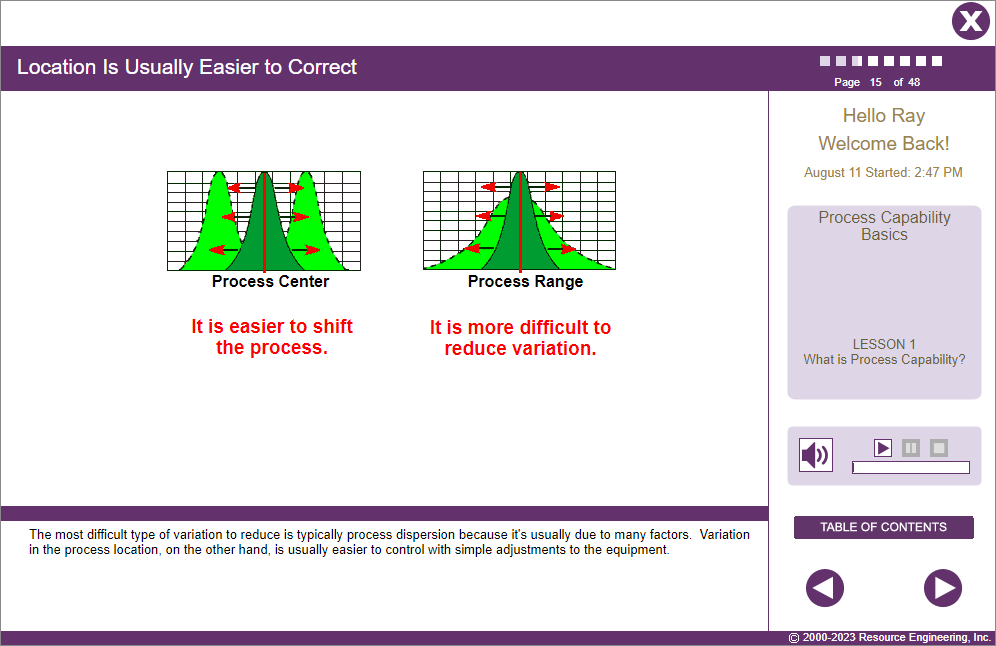

Process Capability is a statistical concept that helps us determine if our existing process is able to meet our customers’ requirements. A process capability study brings together the notion of a stable predictable process with the customers specifications to assess whether the process is capable of meeting the customers’ needs.

This course provides a basic understanding of what process capability is and how it is statistically measured. Process Capability Ratio (Cr) and Process Capability Index (Cp) are covered to help understand the basic concept of process capability and then Cpk is explained and presented as a better measure of true process capability. For comprehensive training on how to use control charts and their underlying principles, we recommend our Basic SPC training.

This Course is Derived from Basic SPC Training This course is a great way to quickly learn about the concepts of process capability. It is taken from our comprehensive Basic SPC course. If you have already taken the Basic SPC course, you have already seen the content in Control Chart Basics.

- Basic math skills.

- An understanding of basic concepts of variation, process stability and statistical process control.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe what is meant by a capable process.

- Contrast the difference between an “in-spec” process and a “capable process.”

- Identify and explain the three main measures of process capability.

Course Outline

Lesson 1 | What is Process Capability

- What process capability means and why it’s important.

Lesson 2 | Measuring Process Capability

- The capability ratio, process capability index, and Cpk.

Challenge

- An assessment of the learner’s progress in this course.

4.5 out of 5 stars

Comments from Learners About This Course

- Good explanation.

- Good pace and descriptions.

You may also be interested in…

- Basic SPC Training – Comprehensive training in understanding and controlling variation using statistical process control and control charts.

- Advanced SPC Training – Comprehensive training in how to implement statistical process control including setting up control charts and conducting process capability studies.

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.