Course Information

Set-Up Reduction Training

Learners will be able to:

- Describe the benefits of reducing set-up time.

- Explain the five steps to reduce set-up time.

- Slash set-up times by converting internal set-up tasks to external.

About This Course

What is Set-Up Reduction?

Perhaps one of the most important yet underappreciated aspects of lean is reducing the time to set-up or changeover processes from one product to another. Whenever process equipment is being “set-up” or “changed-over” to make the next part, it is not productive and “waste” is incurred. Reducing set-up time converts time equipment is shutdown to be reconfigured to make another product into productive time. When this is achieved, many benefits are realized.

A key concept in reducing set-up time is internal vs. external activity. Internal set-up activities take place during the actual changeover when the equipment is not running. External set-up activities are done before the equipment is shut down for changeover. The more activities that can be shifted from internal to external, the more equipment uptime will be reclaimed.

Reducing the time it takes to set-up equipment increases the available capacity to make more product and leverages the investment in the machinery. If you can “sell the capacity” that becomes available, there is a direct benefit to the bottom line. Reduced set-up times lead to greater operational flexibility providing the ability to respond quickly to customer needs.

Set-Up Reduction Basics Online Training

Set-Up Reduction Basics introduces learners to the importance of quick equipment changeover and teaches the basic tools to reduce set-up time. Participants will learn to distinguish between internal and external set-up activities and will develop skills to be able to shift internal activities to external activities. In addition, they will learn how to measure the results of their efforts and establish a system to continually monitor set-up times to hold the gains they have made.

IMPORTANT!

This course is a great way to learn about set-up reduction. It is taken from our comprehensive Lean for Job Shops course. If you have already taken the Lean for Job Shops course, you have already seen the content covered in Set-Up Reduction.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe the purpose and benefits of reducing set-up time.

- Show the relationship between the Seven Wastes and Set-Up Reduction.

- Identify the key components of set-up reduction and explain the role each plays in reducing set-up time.

- Explain the difference between internal and external set-up time.

- Identify opportunities to:

- Convert internal set-up tasks to external ones.

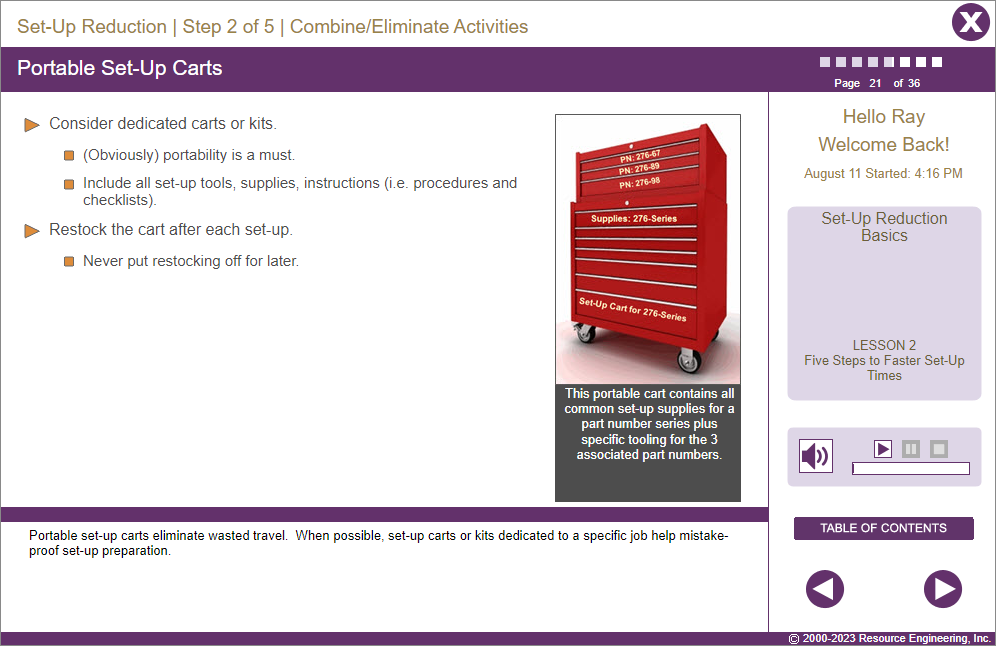

- Combine or eliminate set-up activities.

- Reduce travel and motion.

- Use portable set-up carts.

- Minimize the use of tools and optimize the use of fasteners.

- Monitor and subsequently improve performance.

Course Outline

Lesson 1 | Set-Up Reduction Background

- What is set-up reduction?

- What are the benefits of set-up reduction?

- How do ineffective set-up practices contribute to the “Seven Wastes” especially in the Overproduction, Inventory and Waiting categories.

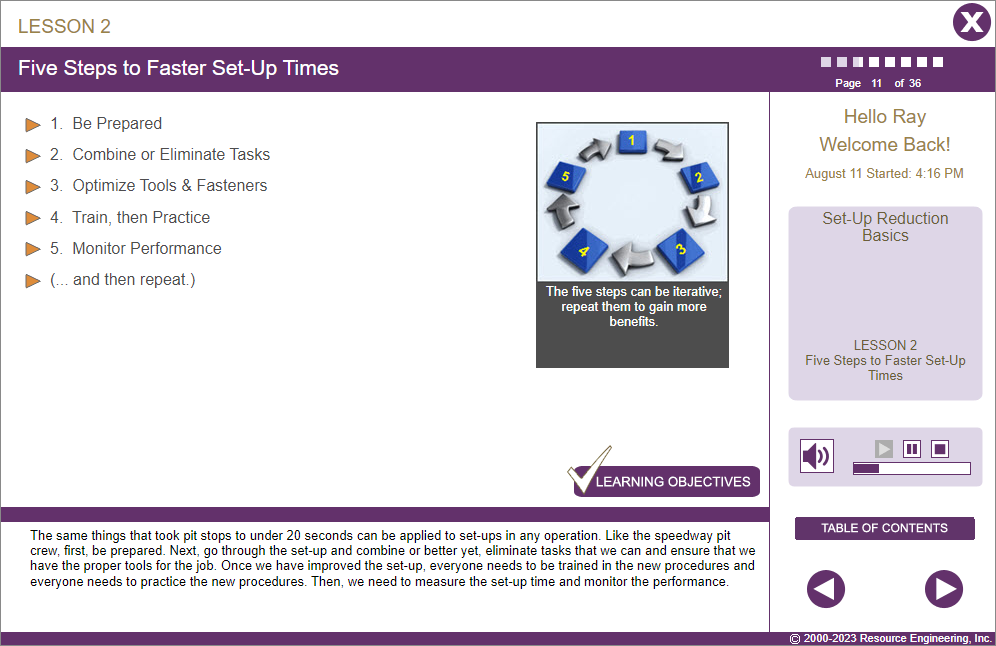

Lesson 2 | Five Steps for Faster Set-Ups

- Be Prepared

- Combine or Eliminate Tasks

- Optimize Tools and Fasteners

- Train, then Practice

- Monitor Performance

- (… and then repeat.)

Challenge

- An assessment of the learner’s progress in this course.

4.6 out of 5 stars

Comments from Learners About This Course

- Useful to start activities related with SMED for operators.

You may also be interested in…

- 5S’s: Workplace Organization – Comprehensive training in the concepts and application of the 5S’s (Sort, Set in Order, Shine, Standardize and Sustain) and how to apply these techniques on the job.

- Lean Manufacturing – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a manufacturing environment.

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.