Resource Centers

R&R Analysis Using ANOVA

Analysis of Variance, or ANOVA for short, is an experimental design technique that looks at a number of variables at the same time.

- It is used to help determine which of the variables under study have a statistically significant impact on the process output.

- With measurement systems, we can explore how the test equipment and appraiser variables affect the measurement system output.

ANOVAs allow us to study four measurement system components:

- Variation between parts or samples.

- Reproducibility between operators or appraisers.

- Repeatability of the measurement equipment.

- Interaction between the samples and the appraisers.

The use of ANOVA does have some advantages over standard GR&R studies:

- ANOVAs provide information on interactions between samples and appraisers.

- With an ANOVA, we can vary the number of samples, appraisers, trials, and even the number of measurement devices to get a more accurate picture of the variation in the measurement system.

- ANOVAs allow us to get an accurate estimate of variances.

- ANOVA techniques are the preferred method for analyzing measurements for destructive testing.

Disadvantage of ANOVA:

- Calculations using ANOVA are more complex than those with other techniques. It is best to use a computer with DOE software for the calculations.

ANOVA Data Format

- A standard 2-factor ANOVA format is used for analyzing measurement systems.

- Factor A is used to designate the parts or samples. Factor B represents the appraisers.

- The number of levels for each factor is a function of the number of samples and the number of appraisers.

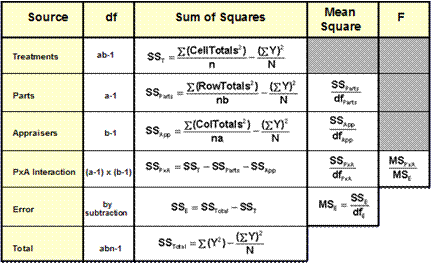

ANOVA Table

Where:

a = number of levels of a

b = number of levels of b

n = sample size per cell

N = total number of measurements made

Mean Square Values

- Mean square values are calculations of variance. The variance is the standard deviation squared.

- Mean square values are calculated for the Parts (MSParts), Appraisers (MSAppraisers), the Parts x Appraisers Interaction (MSPxA), the Error (MSError), and a “Pooled” term MSPool, if appropriate.

PxA Interaction

- We will evaluate the significance of the Parts x Appraisers Interaction using the F-test.

- If this interaction is significant, we will need to investigate the reasons for it.

![]()

- If it is not significant, we will assume it is really part of the experimental error and pool the PxA Interaction value in with the Error Value.

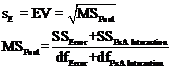

Calculating Repeatability

- If the PxA Interaction is not significant, then the Repeatability statistic, sE, is determined by pooling the MSError and MSPxA.

- If the interaction is significant, then the Repeatability statistic, sE, is determined from the MSError

![]()

Calculating Reproducibility

- The Reproducibility, sA, is determined by the MSAppraisers with a correction term to account for confounding from the instrument variation.

- If the PxA Interaction is not significant:

R&R Calculations

- If the PxA Interaction is not significant, the R&R is simply:

![]()

- If the PxA Interaction is statistically significant, the R&R calculation is more involved:

![]()

where:

![]()

r=number of trials

R&R as a % of the Total Tolerance (TT)

![]()

- We prefer the measurement system to take up less than 10% of the Total Tolerance. If it takes up 30% or more of the TT, the measurement system needs work.

R&R as a % of the Total Variation (TV):

![]()

- If the %GR&R is greater than 30% of the total variation, then the measurement system should be improved.

- To calculate the percentage of the total variation taken up by the measurement system, we need to know both the Part Variation (PV) and the Total Variation, TV.

- If the PxA Interaction is significant:

![]()

- If the PxA Interaction is not significant:

![]()

- With PV known, TV can be calculated:

![]()

Contribution of MSA to Total Variation:

- We can also calculate the contribution that the measurement system actually makes to the total variation. The formula for the % Contribution is:

![]()