Course Information

TPM Basics Training

Learners will be able to:

- Describe the value of TPM and explain the benefits of Total Predictive Maintenance.

- Use the three sequential Phases of TPM to improve upon traditional equipment maintenance.

- Calculate and analyze Overall Equipment Effectiveness (OEE).

About This Course

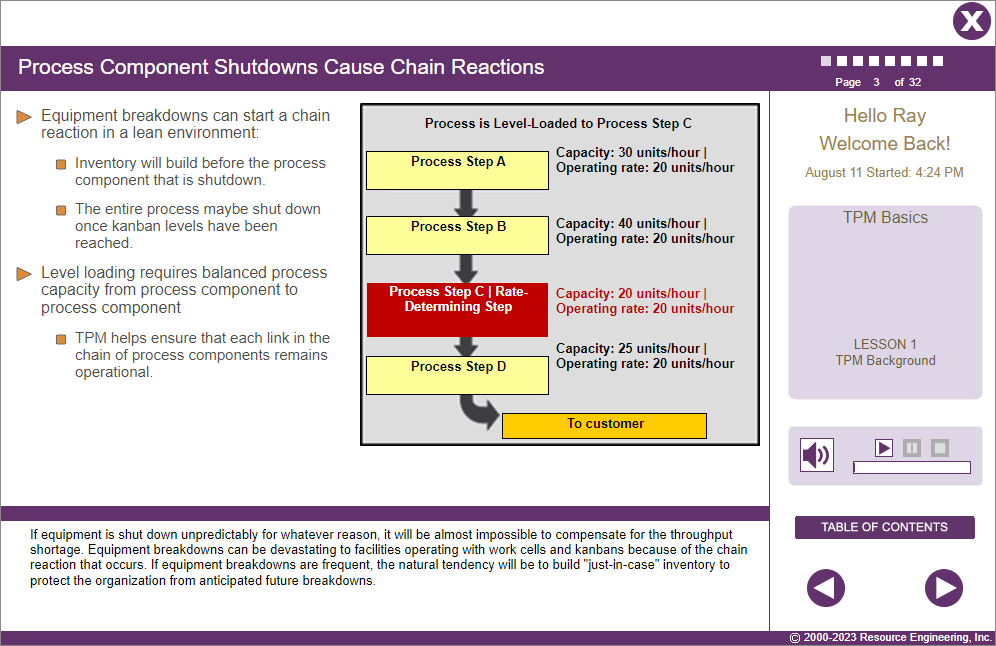

Lean organizations strive to reduce waste in all phases of the operation. Some of the least understood and most overlooked sources of waste relates to the condition and maintenance of processing equipment. One premise of Lean Manufacturing is that equipment is ready to run whenever it is needed (to meet customer demands). If the equipment is unexpectedly shutdown in order to be repaired, critical deliveries may be missed. Poor equipment maintenance rekindles the “old” thinking that extra product inventory is needed as an insurance policy just in case process equipment is not operational thereby undermining Lean efforts, adding more waste.

A TPM effort focuses the organization on keeping equipment functioning optimally by reducing the frequency of breakdowns, the need for long, costly rebuilds and by circumventing many equipment malfunctions and intermittent equipment problems. To this end, much of the day-to-day responsibility for routine maintenance is transferred to the person closest to the equipment, the equipment operator.

IMPORTANT!

This Course is Derived from Lean for Job Shops. This course is a great way to learn about Total Productive Maintenance. It is taken from our comprehensive Lean for Job Shops course. If you have already taken the Lean for Job Shops course, you have already seen the content covered in TPM Basics.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Explain how TPM aids Lean efforts and addresses wastes.

- Know the difference between Corrective Maintenance. Preventive Maintenance (PM) and Predictive Maintenance (PdM).

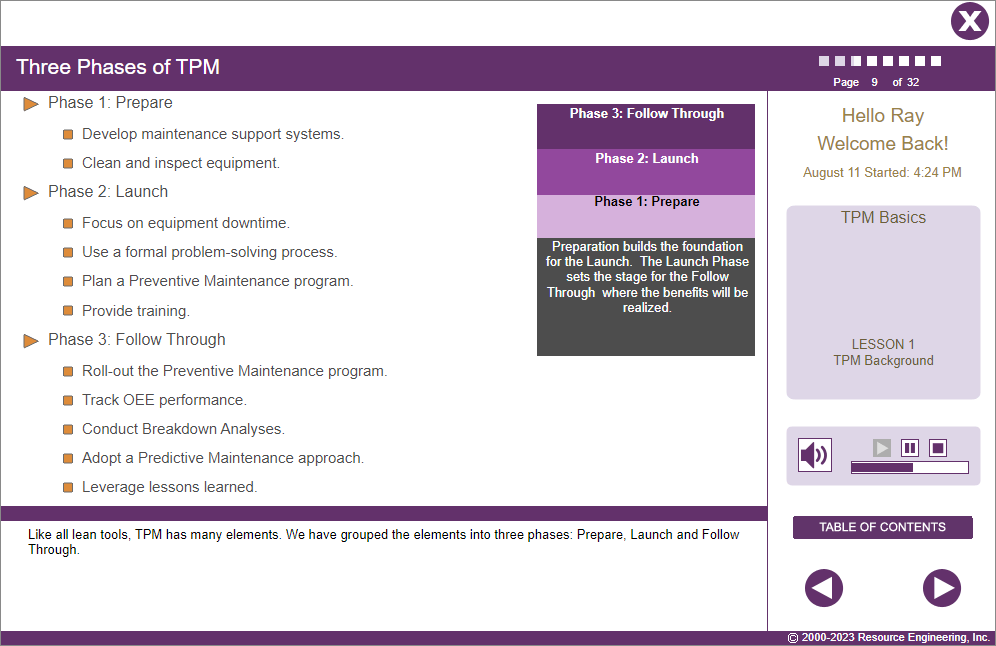

- Understand how the three sequential Phases of TPM build on each other.

- Realize how PdM techniques can further traditional PM practices.

Course Outline

Lesson 1 | TPM Basics

- The importance of equipment reliability in a lean operation.

- How poor equipment reliability contributes to the Seven Wastes.

- Preventive Maintenance (PM) and Predictive Maintenance (PdM).

- Calculating Overall Equipment Effectiveness (OEE)

Lesson 2 | Three Phases of TPM

- Prepare

- Launch

- Follow through

Challenge

- An assessment of the learner’s progress in this course.

4.9 out of 5 stars

Comments from Learners About This Course

- Great course; I wish I could have a copy of it to train operators!

You may also be interested in…

- 5S’s Workplace Organization – Comprehensive training in the concepts and application of the 5S’s (Sort, Set in Order, Shine, Standardize and Sustain) and how to apply these techniques on the job.

- Lean Manufacturing – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a manufacturing environment.

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.