Resource Centers

Automotive PPAP Packages

PPAPs in the Automotive Industry are based on product and process data.

- The PPAP consists of the Documentation Package including the Part Submission Warrant (PSW) and relevant part samples.

- To build the Documentation Package, use data on both the subject product or part and the corresponding process captured from a significant production run to complete the 18 Elements.

Elements of a Automotive Industry PPAP Package

Element 1: Design Record

- The Design Record is typically provided by the customer as the part is usually designed by the customer.

- Including full documentation of the Design Record in the PPAP Package helps ensure that both the suppler and customer are discussing the same part and same revision level.

Element 2: Authorized Engineering Change Documents

- There are times when the PPAP is due to a request for a change to a product or related specification.

- When this occurs, the change request and approval must be included in the PPAP package.

Element 3: Customer Engineering Approval

- Customer Engineering Approval usually refers to (a positive outcome of) a trial at the customer’s facility conducted with production parts from the supplier.

Element 4: Design-FMEA

- A Design-FMEA is a bottom-up analysis of all of the items or components of the design.

- The resulting DFMEA with its corresponding corrective actions become part of the documentation included in the PPAP Submittal Package.

Element 5: Process Flow Diagrams

- Process Flow Diagrams (or flowcharts) document the details of the process.

- All activities and tasks are mapped; decision points, wait periods, feedback loops and rework loops are all documented.

Element 6: Process-FMEA

- A PFMEA is an FMEA on a Process as opposed to a DFMEA, an FMEA on a Design.

- A PFMEA is a structured technique that helps a team think through “everything” that may go wrong in a process.

- The severity or impact of each failure is rated, the potential that a specific failure may actually occur is factored in and the probability that the failure can be prevented or at least detected is considered.

- The intent is to identify risks that are unacceptable and initiate corrective plans that mitigate those risks and help make the process more robust.

Element 7: Control Plan

- The primary intent of a Control Plan is to create a structured approach for control of process and product elements while focusing the organization on characteristics important to the customer.

- Control Plans are a compilation of process and product characteristics, test methods to monitor those characteristics, specifications and sampling or testing intervals.

- A Control Plan does include well thought-out reaction plans to be used in case an out-of-control condition occurs.

Element 8: Measurement System Analysis (MSA)

- The analysis of a measurement system involves understanding the uncertainties associated with taking a particular measurement and then, where possible, quantifying those uncertainties.

- The uncertainties that can be quantified (by statistical means) include issues of accuracy, linearity, stability, repeatability and reproducibility.

- A GR&R (Gage Repeatability & Reproducibility) study is used to determine if the measurement device or system can be relied upon or if the measurement system must be improved before it can be used.

Element 9: Dimensional Results

- For the report of Dimensional Results, identify part numbers and change or revision levels.

- For approval, all dimensions must be within the specification tolerances designated by the Design Record.

- Dimensional Results are to be reported for each manufacturing process the supplier will use.

Element 10: Records of Material / Performance Test Results

- Material Tests refer to chemical, physical or metallurgical requirements specified by the Design Record or Control Plan.

- Performance Tests must be performed and results reported for all parts or product materials when performance or functional requirements are specified by the Design Record or Control Plan.

- It is often helpful to include the Design Verification Plan and Report (DVP&R) with the Record of Material and Performance Test submittals. The DVP&R summarizes validation tests performed.

Element 11: Initial Process Studies

- Initial Process Studies are used to evaluate whether a (supplier’s) process can meet Special Characteristics or (Critical Characteristics) defined by the customer.

- Objectives of Initial Process Studies are to determine if production processes are stable, will yield acceptable outputs for critical or special characteristics and are ready to begin process validation builds.

Element 12: Qualified Laboratory Documentation

- Inspection and testing is to be performed by a lab qualified (or accredited) to conduct the types of tests and measurements.

- When submitting test results, include documentation showing that the laboratory is qualified or accredited.

Element 13: Appearance Approval Report (AAR)

- Complete an Appearance Approval Report (AAR) for each part (or series of parts) that have appearance requirements noted on the Design Record.

- If the part or product does not have appearance requirements, the AAR is not required.

Element 14: Sample Production Parts

- The supplier must provide the customer with a sample of the subject part (or parts) for approval.

- The part(s) must come from a significant production run and be the same part(s) referenced in the PPAP package.

- A complete set of data on the subject part(s) must be included in the PPAP package. A photo of the parts is typically included in the PPAP package noting the storage location of the samples.

Element 15: Master Samples

- A Master Sample is to be signed off by both the customer and the supplier when they agree that the sample part meets all the design requirements and any special customer requirements.

- It is often used as the benchmark for future production runs.

Element 16: Checking Aids

- Checking Aids are special (and sometime custom) tools used to inspect, test or measure parts during the production process.

- Even if Checking Aids have been developed informally, they need to be controlled just as any “formal” gage.

Element 17: Records of Compliance with Customer-Specific Requirements

- All requirements over and above the standard PPAP documentation level specified by the customer are included in this element.

- If no Customer-Specific Requirements are required, it is prudent to include a waiver that none exist.

Element 18: Part Submission Warrant (PSW)

- The PSW is a summary of the PPAP submission complete with all applicable data for the 18 Elements.

- A PSW is required for each of part or part number.

- If bulk materials are used in the production of customer’s parts, they are eligible for a Warrant. However, a PPAP Warrant for the Bulk Material is NOT required unless the customer specifies it. If specified, a completed Bulk Material Checklist and Warrant is needed for bulk material used in production parts.

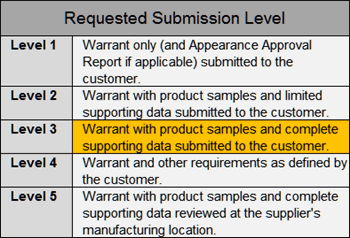

Levels of Submission

- There are 5 Levels of Submission for a PPAP Package; the levels have increasing higher levels of requirements for the supplier.

- Unless otherwise requested by the customer (or negotiated with the customer) the supplier should use submission requirements for the default level, Level 3.