Resource Centers

What is PPAP?

PPAP (Production Part Approval Process) was developed by AIAG (the Automotive Industry Action Group) and it is an important part of the comprehensive Advanced Product Quality Planning (APQP) approach.

Automotive and Aerospace PPAP Processes

It is important to note that the Aerospace Industry has adapted and modified the PPAP process for their suppliers. The industry that you serve and the requirements of your customer will determine which PPAP format you use.

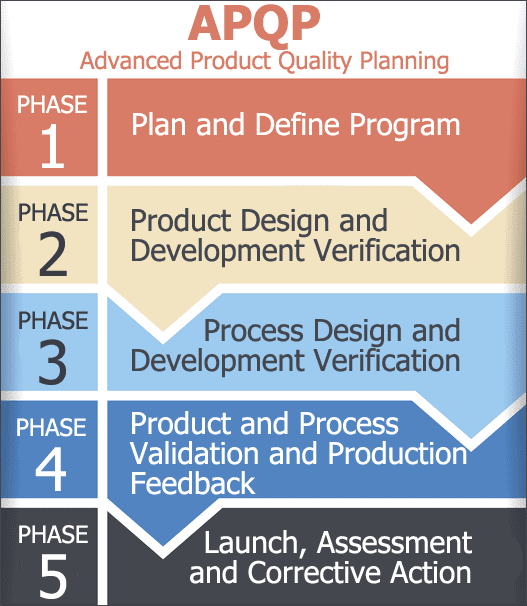

Where PPAP Fits into APQP

There are five phases to APQP; PPAP is triggered in Phase 4, Product & Process Validation.

On the surface, PPAP can appear to be complicated and even overwhelming. Once it is understood, it becomes apparent that PPAP requirements represent the culmination and reporting of activities that any “good” supplier already does.

The PPAP Process merely helps put the reporting of activities and their results into a structured and consistent format. PPAP requirements represent the culmination and reporting of activities that any “good” supplier already does.

A major objective of PPAP is for suppliers to provide their customers with:

- Evidence that customer requirements are understood and…

- Demonstrate that the supplier’s process has the capability to produce product that consistently meets those requirements.

A PPAP is required when production of a new product or part is planned and when there is any significant change to a product or process.

- PPAP is an output of Phase 4, Product & Process Validation, of the APQP process. The ongoing use of PPAP ensures risk will be minimized through effective change control.