Course Information

Value Stream Mapping Training

Learners will be able to:

- Describe how Value Stream Mapping can be used to improve the process.

- Create a Current State Map to identify non-value-added activities.

- Develop a Future State Map the captures planned improvements.

About This Course

What Is Value Stream Mapping?

A value stream is another term for a process that has inputs, performs work on those inputs, and generates an output that has added value. The basic premise of a value stream is that value is added as goods or services stream through the process. Unfortunately, some actions, task, and activities continued within most all value streams do not add value; those non-value-adding task or activities represent waste in the process or value stream.

Mapping the value stream creates a visual representation of the value stream that helps point out the waste contained within the process flow. A value stream represents all of the activities and tasks needed to produce a product. Value streams start with the source of raw materials, flow through the internal processes and continue with the delivery of the product to customers.

Value Stream Mapping Online Training

In this targeted online training, learners will gain an understanding of the purpose of conducting a value stream analysis and what a value stream map is. Steps to streamline a value stream from current state to future state are presented.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe the purpose of a Value Stream Map.

- Identify the key components of a Value Stream Map.

- Explain the key steps in developing the Future State Map.

- Understand the purpose of streamlining the value stream.

- Describe the steps to streamline a workflow.

- Identify the key characteristics of a lean value stream.

- Compare and contrast the difference between a macro and micro workflow.

- Describe the impact of a bottleneck on a process.

Course Outline

Lesson 1 | Value Stream Analysis

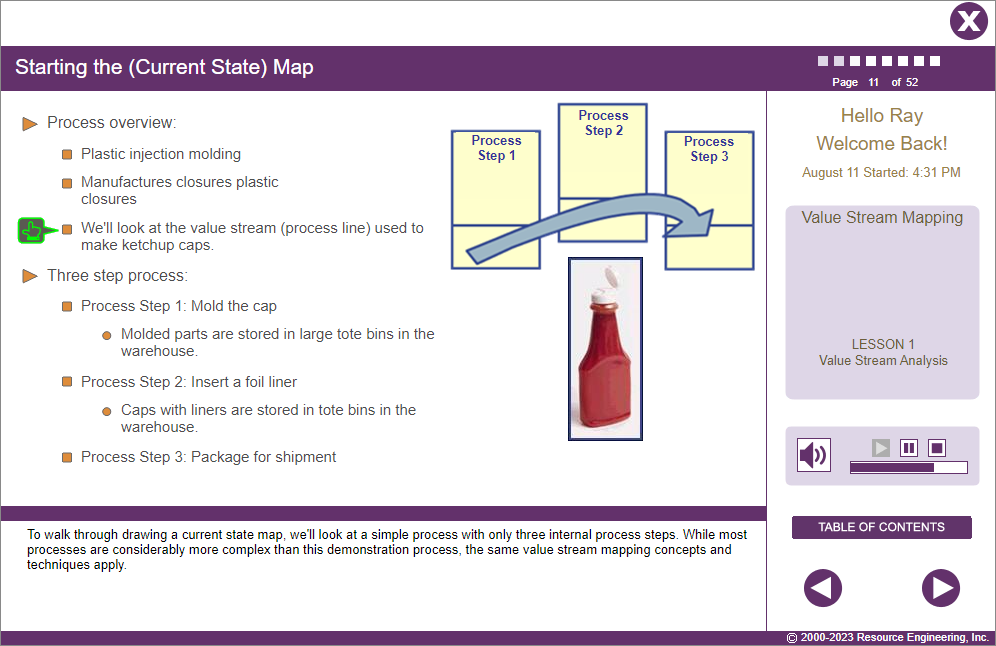

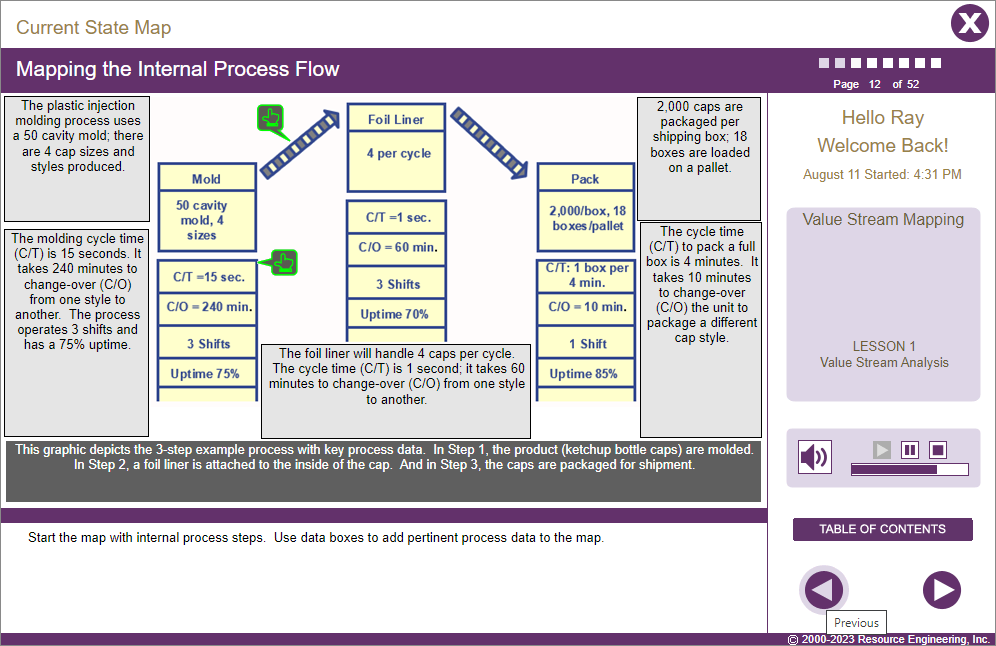

- Defining what the Value Stream is and why is should be mapped.

- How to use process flow mapping symbols to show the flow of the process – both the current state and the desired future state.

Lesson 2 | Streamlining the Value Stream

- Using the Value Stream Map to understand sources of waste and then to conduct a work analysis and then to create a macro workflow and finally a micro workflow.

- Focus on the characteristics of a lean value stream and how to build those into the future state.

Challenge

- An assessment of the learner’s progress in this course.

4.6 out of 5 stars

Comments from Learners About This Course

- It is a pretty good training with the proper information needed to understand in a good way all related to the VSM tool.

You may also be interested in…

- 5S’s Workplace Organization – Comprehensive training in the concepts and application of the 5S’s (Sort, Set in Order, Shine, Standardize and Sustain) and how to apply these techniques on the job.

- Lean for Business Processes – Online training that provides learners with a comprehensive understanding of how Lean Manufacturing works in a transaction-based/non-manufacturing business or job function.

- Mapping Office Workflows – Targeted training in various techniques to map workflows in non-manufacturing environments.