Resource Centers

Cost of Quality: The Hidden Factory

This scenario, harsh as it sounds, is a reality. Even though no one goes to work in the morning with the intention of making junk, by understanding our cost of quality, we can quantify the number of equivalent work hours that are spent in this “hidden factory, hidden hospital,” or “hidden [you fill in the blank].”

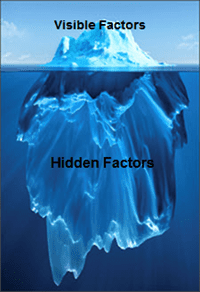

Visible vs Hidden Costs

Some costs of poor quality are obvious – there’s the cost of scrap and rework, the cost of inspection and the cost of training people to find and fix problems. But lurking beneath those obvious costs are a whole lot of other expenses that we often don’t think about and that can be difficult to measure.

By understanding and measuring Costs of Quality, you have a way to identify both the visible and hidden quality factors that impact your bottom line.

Measuring the Cost of Quality

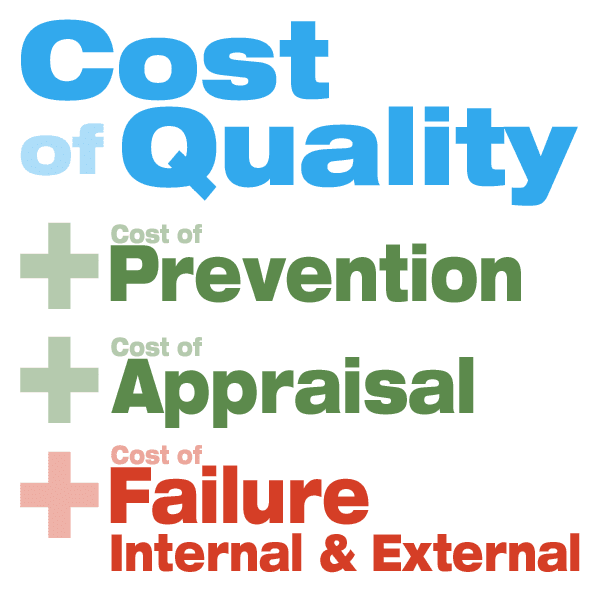

Cost of Quality provides a way to quantify the costs to a business for making, finding, fixing and preventing poor quality. It is made up of four components:

It helps to think of these costs broken down into three categories:

- Prevention or the cost of training, preventive maintenance and engineering improvements to prevent problems from occurring.

- Appraisal or the cost of finding problems including inspection and testing.

- Failure costs or the costs incurred when something goes wrong. Failure costs can be further broken into internal and external failures. Internal failures are discovered in-house before they get out to the customer and external failures are discovered after product or service delivery to the customer.