Course Information

APQP for Aerospace

Learners will be able to:

- Understand the purpose, benefits, and structured phases of APQP based on the SAE AS9145 Aerospace Standard.

- Apply quality improvement tools and techniques throughout the five APQP phases.

- Explain how PPAP is used to communicate product quality status to customers.

About This Course

Master APQP for Aerospace: Elevate Product Development in the ASD Industry

Ready to take flight with your product quality planning?

Whether you’re working in aviation, space, or defense, this course will equip you with the tools and insights to confidently apply the Advanced Product Quality Planning (APQP) process as defined by the AS9145 aerospace standard—the industry’s blueprint for launching successful new products and processes.

APQP for Aerospace is your fast track to mastering a standardized, structured approach for product and process development across the ASD supply chain. Learn how to speak the same language as your customers and drive quality from concept to launch—on time, on budget, and to spec.

🚀 What You’ll Learn:

-

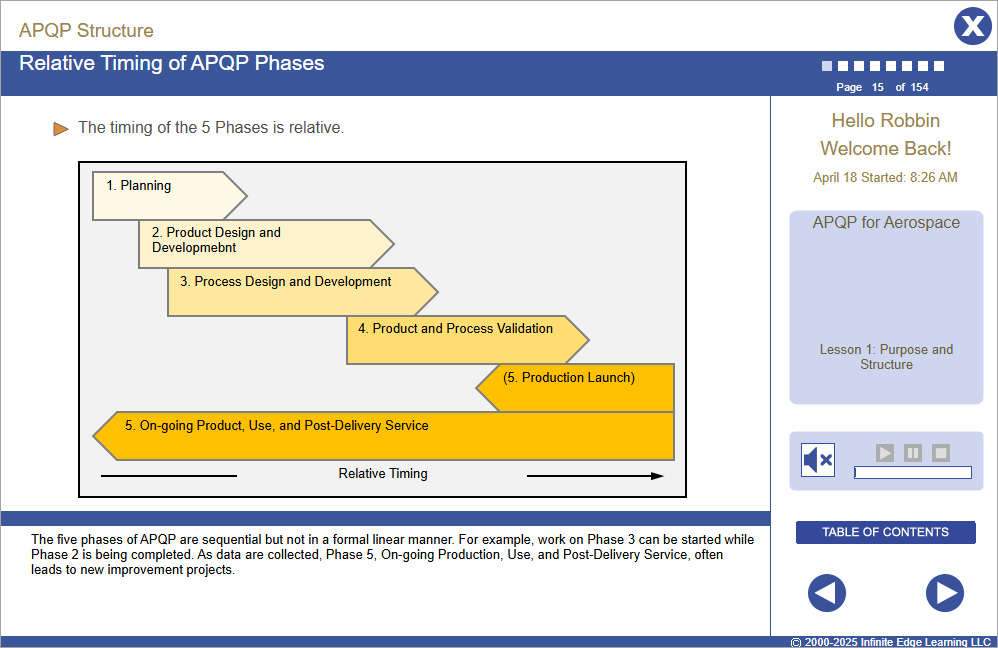

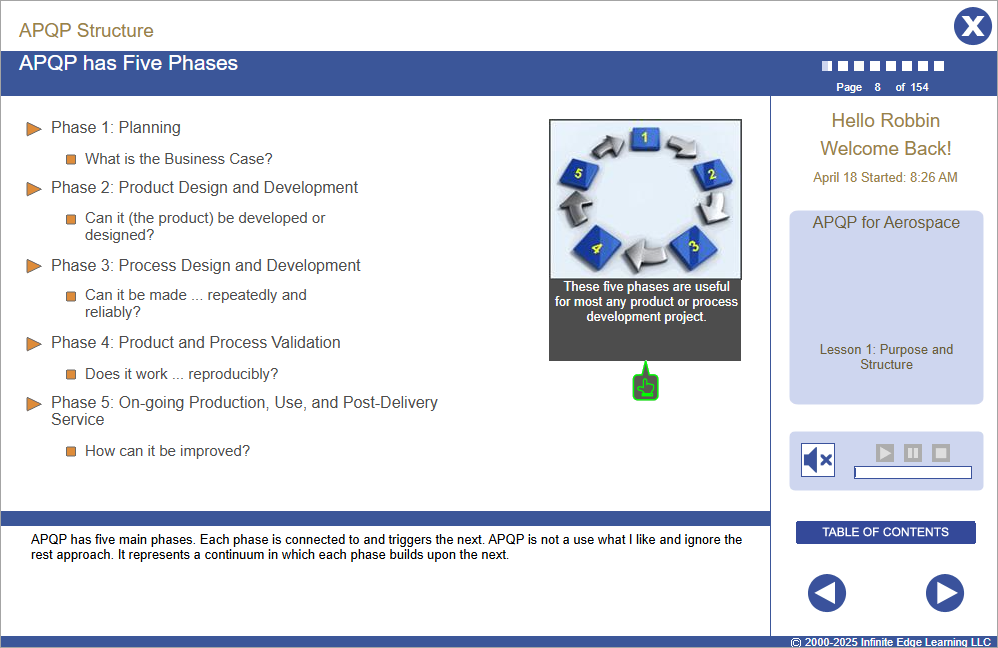

The why and how behind APQP and its five sequential phases

-

How to assess the feasibility and business case for your project

-

How to turn customer requirements into robust design and process plans

-

How to validate products and processes before launch

-

What it takes to execute a successful production launch

-

How to navigate the Production Part Approval Process (PPAP)

-

Continuous improvement tools that help sustain success

📚 Course Format:

-

7 engaging lessons with interactive content and visuals

-

A final Challenge Test to reinforce key concepts

-

Immediate access, learn at your own pace—anytime, anywhere

✈️ Who Should Take This Course:

Engineers, quality professionals, project managers, and anyone involved in product development or supplier collaboration in the aerospace industry.

None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Explain the purpose and benefits of the APQP process and use the sequential phases of the APQP process.

- Learn how to assess the practicality and feasibility of the Business Case.

- See how inputs for the process design are generated using customer requirements.

- Understand how the process is developed using the product design, process flow and layout concepts as inputs.

- Be aware of how both the product and process are validated to meet customer requirements.

- Be cognizant of the conditions needed for a production launch,

- Be familiar with the Production Part Approval Process (PPAP).

- Know about tools and techniques that are used to continuously improve both the product and its corresponding process.

Course Outline

Lesson 1 | APQP Purpose & Structure

- To understand why the APQP process is crucial to the viability of the organization’s business.

- Become familiar with the structured approach for implementing APQP.

Lesson 2 | APQP Phase 1: Planning

- Explain how customer needs and expectations can be translated into a value-added (and competitive) offering.

- Become familiar with the design, reliability, and quality goals of the Planning Phase.

Lesson 3 | APQP Phase 2: Product Design and Development

- Understand how to use technical, quality, and cost requirements to validate the product design.

- Be aware of how to conduct a preliminary feasibility assessment of whether the manufacturing process is capable of producing the product.

Lesson 4 | APQP Phase 3: Process Design and Development

- Understand how the production process is defined, established, and verified.

- Be exposed to the primary tools and techniques used to verify the capability of the production process.

- Learn what is involved in conducting the PRR (Production Readiness Review) and how to address shortcomings if any are found.

Lesson 5 | APQP Phase 4: Product and Process Validation

- Know how to validate that the designed product meets all requirements and that the manufacturing process is capable of consistently producing conforming products at the customer’s desired rate.

- Understand the role of Production Process Runs (PPRs) and First Article Inspections (FAIs) in preparing the Production Part Approval Process (PPAP).

Lesson 6 | APQP Phase 5: On-going Production, Use, and Post-Delivery Service

- Describe how inputs are collected and compiled for improving the product and process.

- Explain techniques for reducing common cause variation, addressing customer satisfaction issues, improving delivery and service issues, and applying lessons learned.

Lesson 7 | Best Practices

- Know about best practices that help get the most out of the APQP structured improvement approach.

New Course: Reviews will be available after the course has an adequate number of reviews.

You may also be interested in…

- Control Plans – This course teaches practitioners how to create and apply effective Control Plans by exploring their purpose, role in the Quality Planning Cycle, connection to APQP phases, and best practices for implementation.

- PPAP for Aerospace – This course teaches how the PPAP process works in the Aerospace Industry, how it relates to APQP, and walks through each of the 11 elements of a PPAP in the Aerospace Industry.

- Advanced SPC Training – Comprehensive training in how to implement statistical process control including setting up control charts and conducting process capability studies.

- FMEA Training – Complete online training in how to conduct Design and Process FMEAs and to reduce high Risk Priority Numbers, how to customize FMEAs for a specific business and how to maintain improved processes using a control plan.

- Measurement Systems Analysis – Comprehensive training in how to statistically measure the accuracy and reliability of measurement systems.