Course Information

Control Plans Training

Learners will be able to:

- Use the NEW 2024 Control Plans Guidelines (following the AIAG Reference Manual) to ensure products and the processes that create them, meet customer requirements.

- Minimize process and product variation by assuring all process outputs are in a state of control at every step of the product and process life cycle.

- Develop a control plan that summarizes the key product, process, and special characteristics, the associated methods used to measure and monitor output and the action plan including who is accountable in the event that the characteristic measured falls outside of the acceptable range of variation.

About This Course

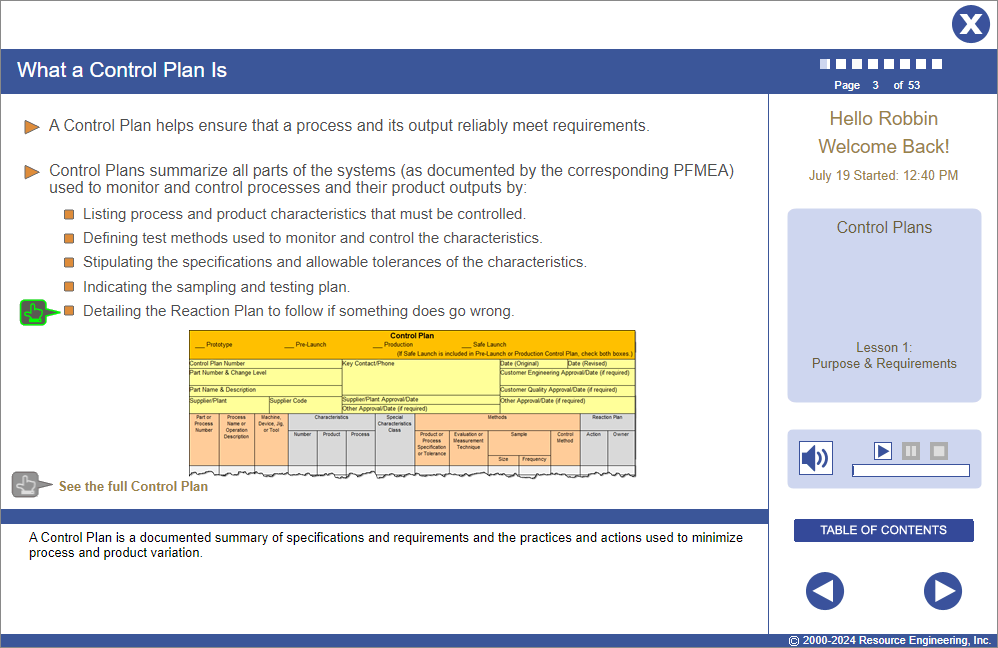

The intent of a Control Plan is to create a structured approach for control of process and product elements while focusing the organization on characteristics important to the customer. An important part of a Control Plan is a Reaction Plan that clearly specifies what action to take in case an out-of-control condition occurs and who is responsible for taking the action.

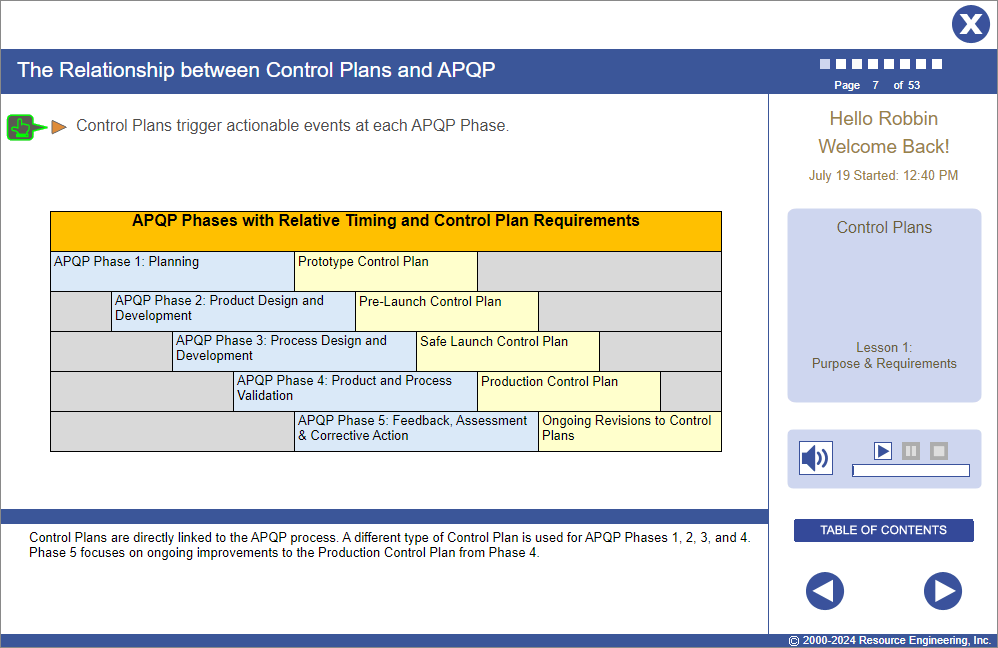

Development and use of Control Plans are a vital aspect of a comprehensive Advanced Quality Planning Process (APQP). The Advanced Quality Planning Process was originated by the Automotive Industry Action Group to provide a common, standardized process for planning, developing and communicating the requirements and status of new products and services to improve the process for New Product Introductions (NPI). The type of control plan used is dictated by the APQP phase. Control Plans should be used in the Prototype, Pre-Launch, Production, and Safe Launch phases.

This course focuses on the AIAG 1st Edition Control Plans Reference Manual released in March 2024.

This course teaches practitioners how to create and use Control Plans. It explains the purpose of a Control Plan, their significance in the Quality Planning Cycle, how Control Plans apply to the Phases of APQP, and how Best Practices can make them more effective.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Explain the purpose and value of a Control Plan.

- Understand the different types of Control Plans used throughout the APQP process.

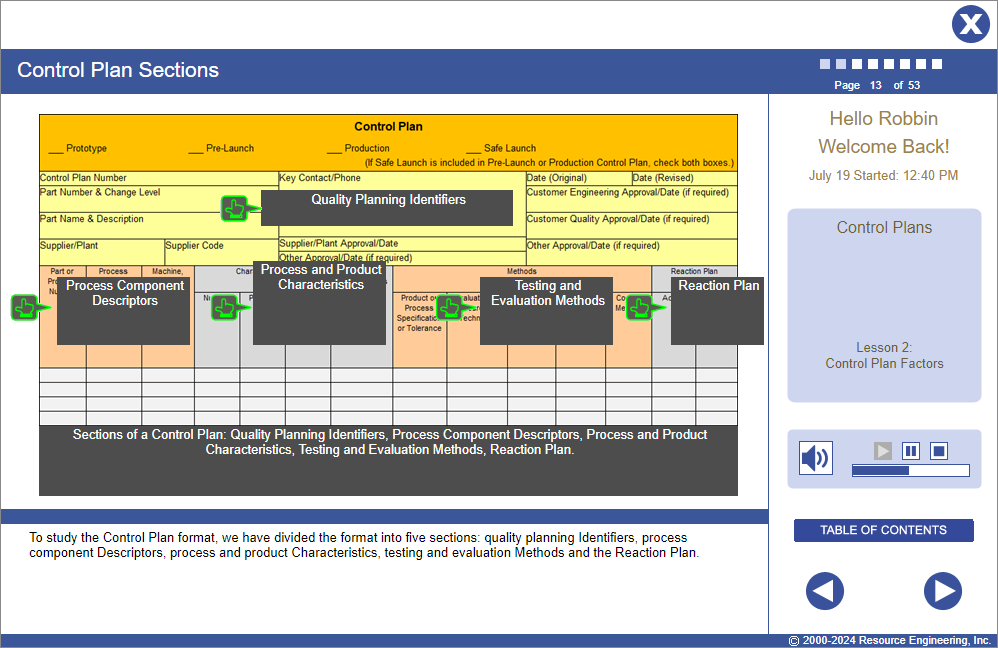

- Describe the key sections of a Control Plan.

- Develop control plans to monitor key Product, Process and Special Characteristics along with a Reaction Plan for each Characteristic should it exceed acceptable variation.

- Implement best practices to get the most from Control Plans.

Course Outline

Lesson 1 | Purpose and Requirements

- What a Control Plan is

- Why Control Plans are Essential

- The relationship between Control Plans and APQP

- Control Plans & the Quality Planning Cycle

Lesson 2 | Control Plans Components

- Sections of the Control Plan

- The Importance of the Reaction Plan

- Rework and Repair Processes

- Other Control Plan Considerations

Lesson 3 | Types of Control Plans

- Why are different types needed?

- Prototype

- Pre-Launch

- Safe Launch

- Production

- Continual Improvements

Lesson 4 | Best Practices

- Assure Control Plans Are Comprehensive

- Verify Controls with Layered Process Audits

- Use Reverse PFMEAs to Identify Gaps

- Consider the Impact of Abnormal Conditions

- Dealing With Highly Automated Processes

- Assess Storage & Handling Risks

- Apply Lessons Learned from Foundation & Family FMEAs

- Some Parting Thoughts

Challenge

- An assessment of the learner’s progress in this course.

This course was launched in July 2024. Check back for a rating after the course has been used for a few months.

Comments from Learners About This Course

- No comments yet for this new course.

You may also be interested in…

- Advanced Product Quality Planning Training – A Master Course that helps learners understand the phases of the APQP process and apply it to the development of new products and their corresponding processes.

- AIAG-VDA Process-FMEA Training – Complete online training in how to conduct AIAG-VDA Process FMEAs, to reduce high risk and improve quality.

- Advanced Control Charts Training – Comprehensive training in how to implement statistical process control including setting up control charts and conducting process capability studies.