Course Information

Introduction to FMEAs Training

Learners will be able to:

- Describe what FMEAs are and why they are used.

- Read and understand an FMEA report.

- Use FMEAs to assess and prioritize risk.

About This Course

What is Failure Mode and Effects Analysis?

Failure Mode and Effects Analysis (FMEA) techniques have been around for over 40 years. In recent years, use of FMEAs has gained popularity as a quality improvement tool. This interest is in large part due to the automotive industry and specifically its IAFT 16949 supplier requirements. Other major industries, including aerospace, medical products and electronics are also using FMEA techniques as part of their improvement and risk assessment strategies. Unlike many quality improvement tools, FMEAs do not require complicated statistics. FMEA studies can yield significant savings for a company as well as reduce the potential liability of a process or product that does not perform as promised.

Introduction to FMEAs Online Training

This online training introduces learners to the basic concepts of conducting a Failure Mode and Effects Analysis. It is ideal for managers and supervisors who oversee teams responsible for conducting FMEAs, but who will not be actually serving on the FMEA team. For more in-depth, step-by-step training see Design FMEAs or Process FMEAs. For the 2019 AIAG-VDA FMEA Methodology, see AIAG-VDA Design-FMEAs or AIAG-VDA Process-FMEAs.

- None.

- English (EN-US)

- Chinese (simplified) (ZH)

- Czech (CS)

- French (FR)

- German (DE)

- Italian (IT)

- Japanese (no audio) (JA)

- Korean (no audio) (KO)

- Polish (PL)

- Portuguese (Brazilian) (PT-BR)

- Romanian RO)

- Russian (RU)

- Spanish (ES)

- Vietnamese (no audio) (VI)

Course Objectives

- Describe what an FMEA is and why an FMEA is used.

- Explain the differences between a Design-FMEA and a Process-FMEA.

- Explain how the systematic FMEA approach getting us to dig into the details of the product or process under study to identify potential risks.

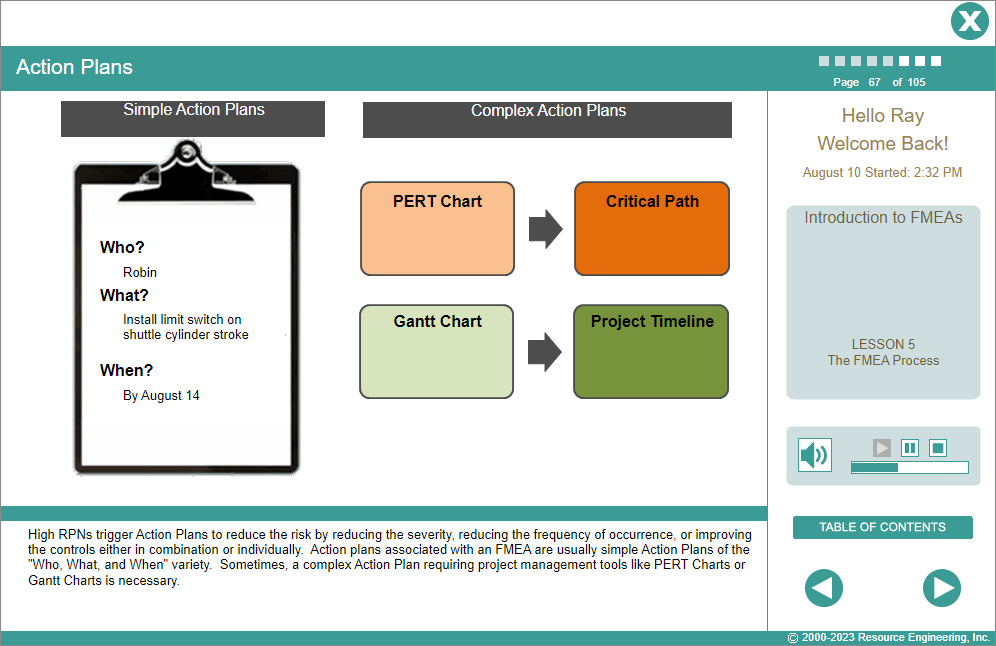

- Define how an FMEA helps identify risks, prioritizes the risks relative to one another, and focuses efforts on an action plan to reduce the risks.

- Apply criteria to assemble and effective FMEA team.

- Describe the role of a Subject Matter Expert when conducting an FMEA study.

- List the 10 steps used to conduct an FMEA.

- Explain how the standard FMEA Analysis Worksheet is used to organize data and present the findings of an FMEA study.

Course Outline

Lesson 1 | What is an FMEA?

- An overview of what an FMEA is; how the FMEA process works; and why an FMEA is used.

Lesson 2 | Purpose of an FMEA

- An explanation of how an FMEA helps identify risks, prioritizes the risks relative to one another, and focuses efforts on an action plan to reduce the risks.

Lesson 3 | Adding-Value with FMEAs

- Six important ways FMEAs add-value.

Lesson 4 | Types of FMEAs

- An explanation of the differences between a Design-FMEAs, Process-FMEAs and Software-FMEAs.

Lesson 5 | The FMEA Process

- A preview of the 10 steps used to conduct an FMEA. The same basic steps apply to both a DFMEA and a PFMEA.

Lesson 6 | Assembling an FMEA Team

- Helpful hints on assembling an effective FMEA team.

Lesson 7 | Best Practices for Conducting FMEAs

- Six best practices to get the most out of FMEA studies.

Challenge

- An assessment of the learner’s progress in this course.

4.7 out of 5 stars

Comments from Learners About This Course

- Very good introduction to FMEA process.

- Very informative and good introduction to what seems to be a potentially complex subject. Good to get things started in my organization.

- Great introduction into FMEAs!

You may also be interested in…

- Mistake-Proofing Training – Comprehensive online training in poka yoke/mistake-proofing techniques for manufacturing operations.

- 8D Problem-Solving – Step-by-step training in how to work on a problem-solving team follow the 8D methodology including tools and techniques that are used in each step.

- Root Cause Analysis with Corrective Action – Leads the learner through a four-step process to get to the root cause (source) of problems to eliminated problems for good.