Resource Centers

Process Measurement Instrumentation

Temperature

Temperature measurements can be made with contact or non-contact devices. When the temperature device is used in conjunction with a controller, the process can be shut down when the temperature begins trending too high or too low.

Pressure

- A common mistake-proofing technique is to install a pressure monitor on the compressed air system and to shut down the process when the pressure gets too low. This prevents pressure sensitive devices such as air cylinders from malfunctioning.

Electrical Load

- If the amperage or power drawn exceeds preset limits, the process can be shut down. Careful planning needs to take place on how the process should be shut down.

Flow

- Liquid flow can be measured with rotameters, flow-switches, and other devices. Gas flow can be detected with flow-switches, pitot tube devices, and anemometers. These are often used to mistake-proof processes by shutting them down when there is low flow or no flow.

Motion Control

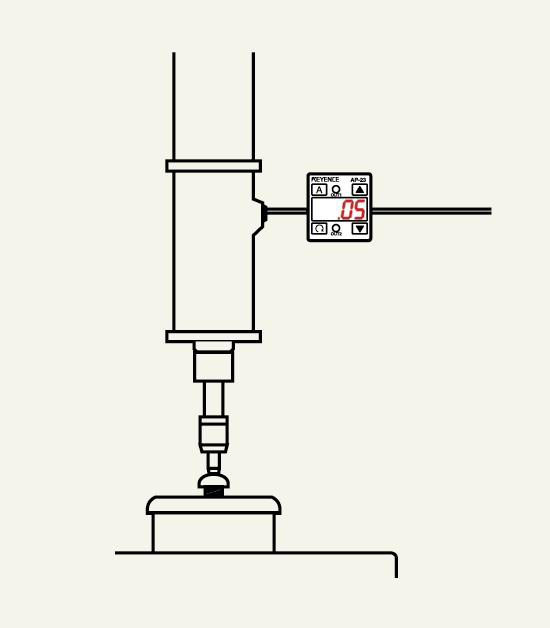

Some motion control devices work on the same principle as ABS brakes. A sensor detects pulses from a disk rotating with the drive shaft on the conveyor. If there is no motion when there should be, then the process is shut down.

Speed

- Motor and process equipment speeds can be measured with a variety of devices. These devices can shut down the process if the speeds get too high or too low.

Viscosity

- In-line viscosity measurements are used in the process industries to ensure the proper ingredients have been added and to ensure the fluid can be processed. These measurements can trigger alarms or in extreme cases, shut down the process.

pH

- Plating baths and other solutions can be mistake-proofed by using pH monitors.

- Rather than having the operators titrate to check the pH, the pH monitor and controller could shut down the process or automatically adjust the pH to create a forced control solution.

Mass/Weight

- Weight or mass measurement devices can be used to deliver a steady feed rate of input materials to a process.

Humidity

- Some processes can be affected by the humidity being too high. And some processes become unsafe because of static build-up when the humidity gets too low.

- Humidity sensors can be used to shut down a process if either a high or low humidity condition occurs.