Resource Centers

AIAG-VDA 7-Step DFMEA Process

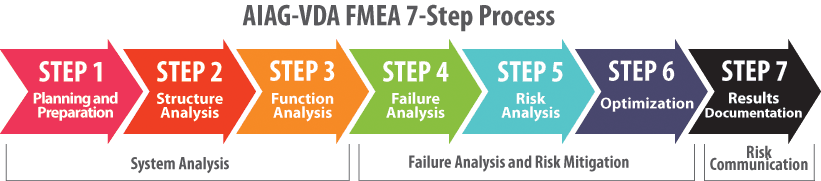

There are 7 steps for conducting an AIAG-VDA DFMEA:

- Planning and Preparation

- Structure Analysis

- Function Analysis

- Failure Analysis

- Risk Analysis

- Optimization

- Results Documentation

The 7 steps are summarized into three phases:

- Steps 1 through 3 represent the “System Analysis” phase of a DFMEA study.

- Steps 4 through 6 represent the “Failure Analysis and Risk Mitigation” phase of a DFMEA study.

- The third phase, Communication, is Step 7, Results Documentation

Step 1: Planning and Preparation

- The DFMEA study starts with a purposeful and careful definition of the scope.

- The management team is responsible for setting the scope of the study.

Step 2: Structure Analysis

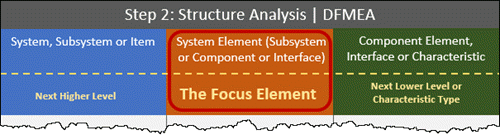

- Structure Analysis is used to identify and breakdown the design into the system, subsystems, assemblies and component elements for DFMEAs.

- The Structure Analysis uses the boundaries set by the Scope Definition (Step 1) to identify every component of the product (design).

- Structure Analysis consists of three expanded columns whose purpose is to facilitate a thorough understanding of the process. Start with the Focus Element in the “middle column,” then identify the System of which the Focus Element is a part and finally identify all Components Elements contained within the Focus Element.

Step 3: Function Analysis

- Think of the Function Analysis step as exploring what the product should be doing and how that functionality is facilitated.

- Using the Structure Analysis developed in Step 2, each element is analyzed separately in terms of its function(s) and corresponding requirement(s).

Step 4: Failure Analysis

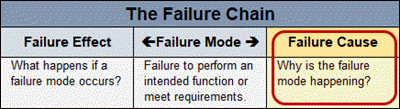

- In Step 4, the concept of a “Failure Chain” is used to visualize failures as part of three links of a chain.

- The Failure Chain is comprised of the Failure Mode (FM), the corresponding Failure Effect (FE) and the Failure Cause (FC).

- A Failure Mode represents any manner in which an item (the Focus Element) could fail to meet its intended function.

- A Failure Effect is the consequence of a Failure Mode.

- A Failure Cause is an indication of why a Failure Mode could occur.

- Analyzing failures involves identifying how the Focus Elements detailed during the Structure Analysis may fail to perform intended functions documented by the Function Analysis.

- A failure mode leads to a failure effect triggered by a failure cause.

- Determining potential causes is at the heart of a DFMEA.

Step 5: Risk Analysis

- In Step 5, the Severity, Occurrence and Detection of each failure chain is evaluated

- An Action Priority Level of “High, Medium or Low,” based on S-O-D evaluations as indicated by the Action Priority Tables.

- The Action Priority Tables do not establish a “risk priority” but rather a priority level for action needed to reduce the risk of failure to function as intended.

- Every potential evaluation combination is assigned a High, Medium or Low priority according to the AP Table.

- If the AP level is High, action to improve prevention and/or detection controls (or justification on why current controls are adequate) MUST be taken.

- If Medium, action to improve prevention and/or detection controls (or justification on why current controls are adequate) SHOULD be taken.

- And if Low, action to improve prevention and/or detection controls COULD be taken.

Step 6: Optimization

- The primary objective of the Optimization step is to develop actions that reduce risk and increase customer satisfaction by improving the product.

- Most actions will likely involve lowering the likelihood of the occurrence of failure causes or improving detection controls; either approach leads to a more robust design.

Step 7: Results Documentation

- The results of each FMEA study should be fully documented.

- An FMEA study is not finished until Step 7 has been completed.

FREE AIAG-VDA FMEA Training Lesson!

| AIAG-VDA FMEAs | AIAG-VDA FMEA MSRs |