Master the Six Core Tools

The Core Tools—APQP, FMEA, MSA, SPC, and PPAP—form the backbone of effective quality planning, risk reduction, and process control. These five methodologies equip organizations with a structured approach to designing, launching, and maintaining reliable products and processes. Whether your team is new to quality or strengthening existing systems, the Core Tools provide the essential foundation for building consistency, reducing defects, and improving overall operational performance.

Core Tools Curriculum by Industry

Originally developed for the automotive sector, the Core Tools are now widely adopted across aerospace, defense, medical devices, pharmaceuticals, electronics, plastics, and general manufacturing. Any industry that relies on complex supply chains, regulatory compliance, or high-precision production benefits from the standardized frameworks these tools provide. By training teams in the Core Tools, organizations can align cross-functional groups, meet customer and certification requirements, and drive a culture of proactive quality improvement across global operations.

Core Tools for Automotive:

- APQP for Automotive

- Control Plans

- AIAG-VDA Process-FMEAs OR AIAG -VDA Design FMEAs

- Basic SPC (Statistical Process Control)

- Measurement System Analysis (MSA)

- PPAP: Production Part Approval Process

Aligned with AIAG/IATF 16949 Core Tools

Core Tools for Aerospace:

- APQP for Aerospace

- Process FMEAs or Design FMEAs

- Basic SPC (Statistical Process Control)

- Measurement System Analysis (MSA)

- PPAP for Aerospace

APQP is based on the SAE AS9145 Aerospace Standard.

Core Tools for the Medical Devices:

Additional Specialized Courses

Enhance your team’s expertise with optional advanced courses that could be added to the Core Tools Curriculum:

- Advanced Control Charts: Deepen understanding of SPC techniques.

- Advanced Process Capability: Master complex process capability studies.

- 8D Problem-Solving: Adopt a structured approach to identifying and resolving problems.

Why Choose Online Core Tools Training?

Traditional classroom training can be resource-intensive and inflexible. Our online Core Tools Training offers a cost-effective, adaptable alternative that fits seamlessly into your team’s schedule. Benefits include:

- Flexible Scheduling: Employees can train at their own pace, integrating learning into their daily routines without extended time away from work.

- Consistent Learning: Ensure all team members acquire the same knowledge and terminology, fostering a unified approach to quality management.

- Tailored Curriculum: Customize training paths to match specific roles and responsibilities within your organization.

- Cost Efficiency: Reduce expenses related to travel and on-site training without compromising on quality.

- Easy Administration: Utilize our Learning Management System (LMS) or integrate courses into your existing LMS for streamlined oversight.

- Immediate Access: Begin training when it suits your schedule—no need to wait for scheduled seminars.

- Available in Spanish, Polish, French, Chinese and More!

Simple Enrollment Process

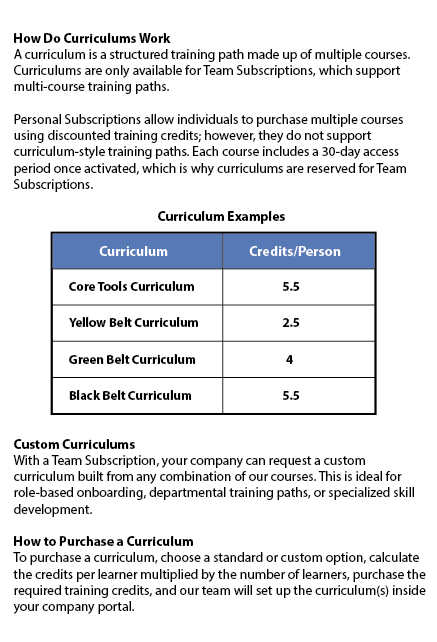

The cost of the Core Tools Curriculum is the same across all industries. Each learner requires 5.5 Training Credits (equivalent to $495) to complete the full set of Core Tools courses. Organizations purchasing credits in bulk receive quantity discounts, allowing companies and work teams to reduce the per-learner cost. Credits can then be assigned to individual employees as they enroll in courses.

- Purchase Training Credits: Determine the number of credits needed based on your selected courses and number of learners.

- Assign Courses: Use our LMS to allocate courses to team members, customizing the curriculum as needed.

- Track Progress: Monitor learner advancement and course completion through our administrative tools.

- Certification: Upon completion, learners receive a Curriculum Certificate, validating their proficiency in Core Tools.

Empower your team with the skills to drive quality improvements and meet industry standards. Contact us to learn more about our Core Tools Training and how it can benefit your organization.